Linear Power Supply

Date: 3/2023

Revision: 1

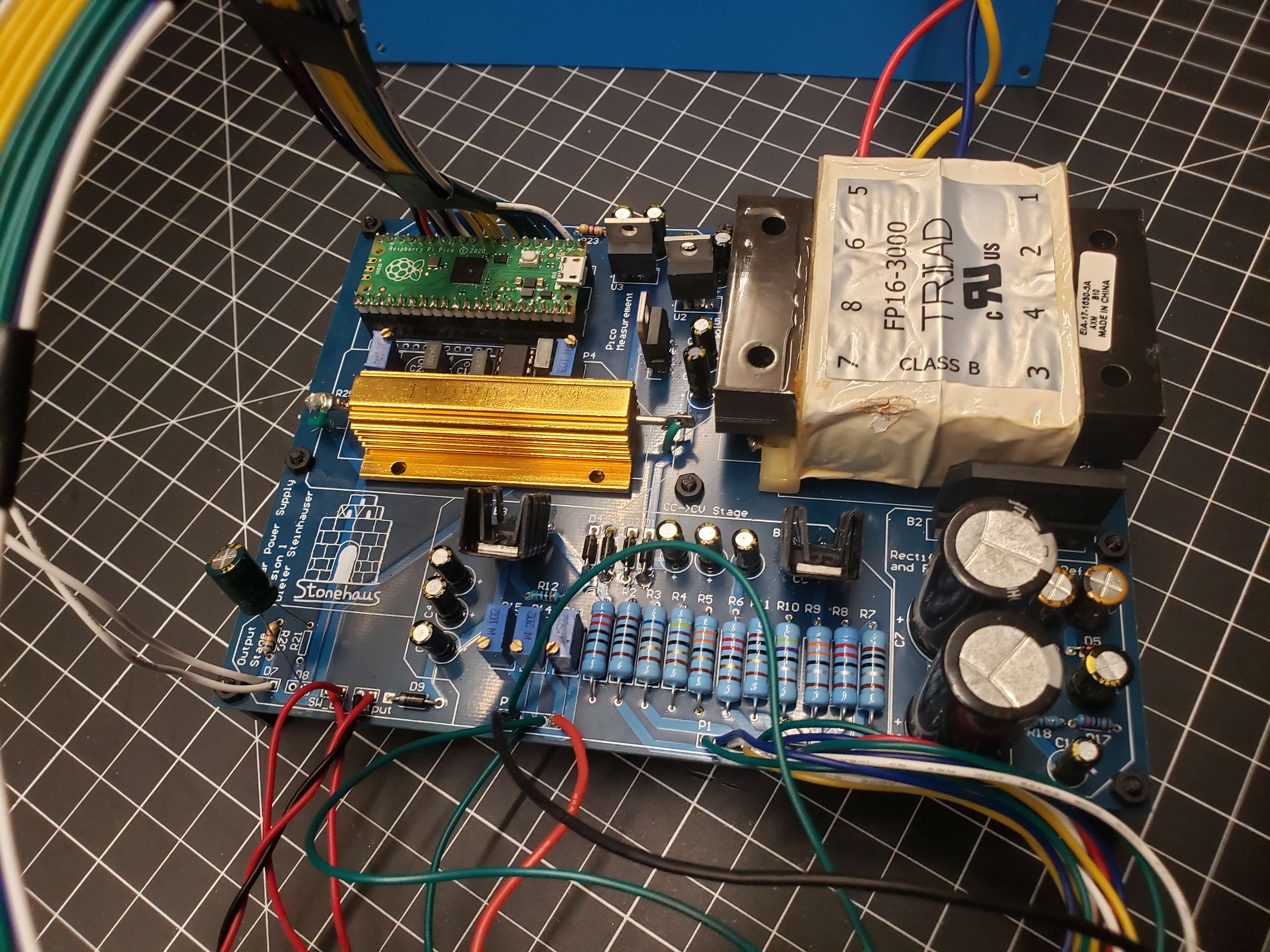

Finished Linear power supply.

Introduction

The purpose and goals of this project are to become familiar with linear power supply design, prepare engineers to transform, regulate, and rectify power for future projects, and create a critical tool for any engineer’s lab. Power transformation, AC to DC rectification, and voltage regulation are key components for practically every electrical project. With this project, we aim to design a 20V/3A linear power supply with adjustable voltage and current limiting capability. We also aim to create a precise voltmeter and ammeter to relay status of the supply.

Methods

See also

This project draws from numerous engineering concepts. For general reference and theory, concepts and components from the pages below are employed. Topics that required greater detail for clarification are revisited.

Project Overview

This linear power supply aims to provide up to 20 volts at 3 amps. The design employs linear regulators to minimize noise of the output, adjust voltage, and a current limit for the device. The power supply will need to be monitored for the output current and voltage. A Raspberry Pico will be employed for taking voltage and current measurements and displaying them on an LCD for the user. LED indicators, reverse polarity protection, and output enable switch are also added for a better user interface. A fuse will also be used for the safety of the user and the device.

Introduction to AC/DC Linear Power Supply

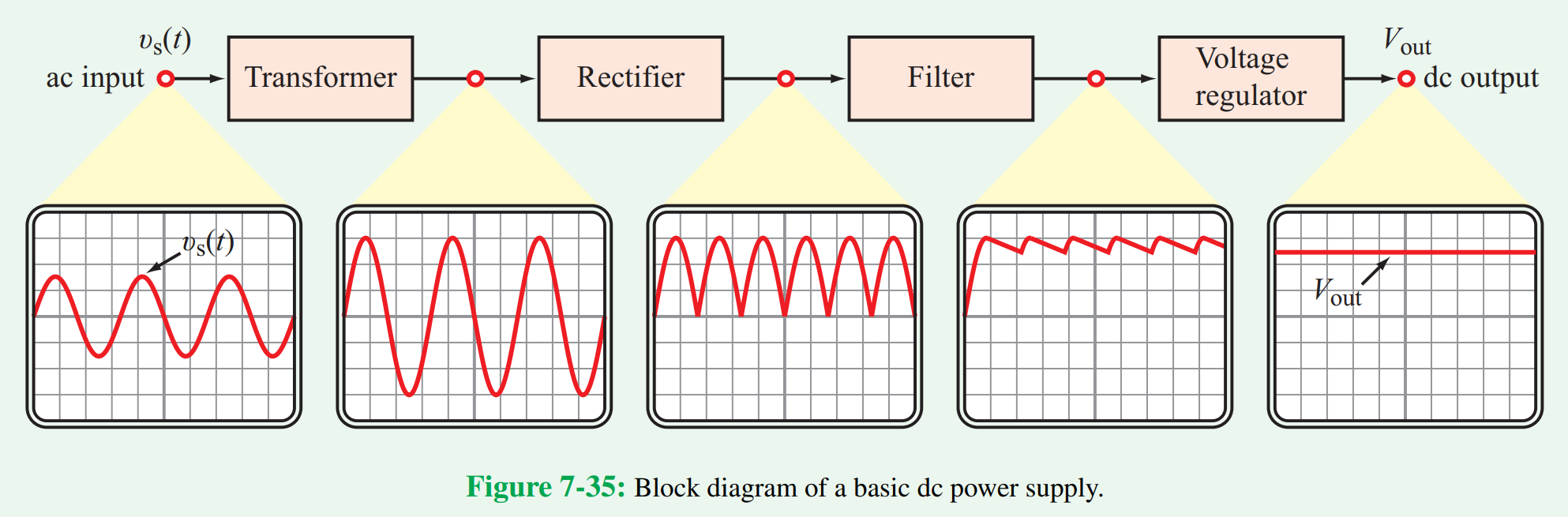

Fig 7-35 of Circuit Analysis and Design 1. Block diagram of a basic AC-DC linear power supply.

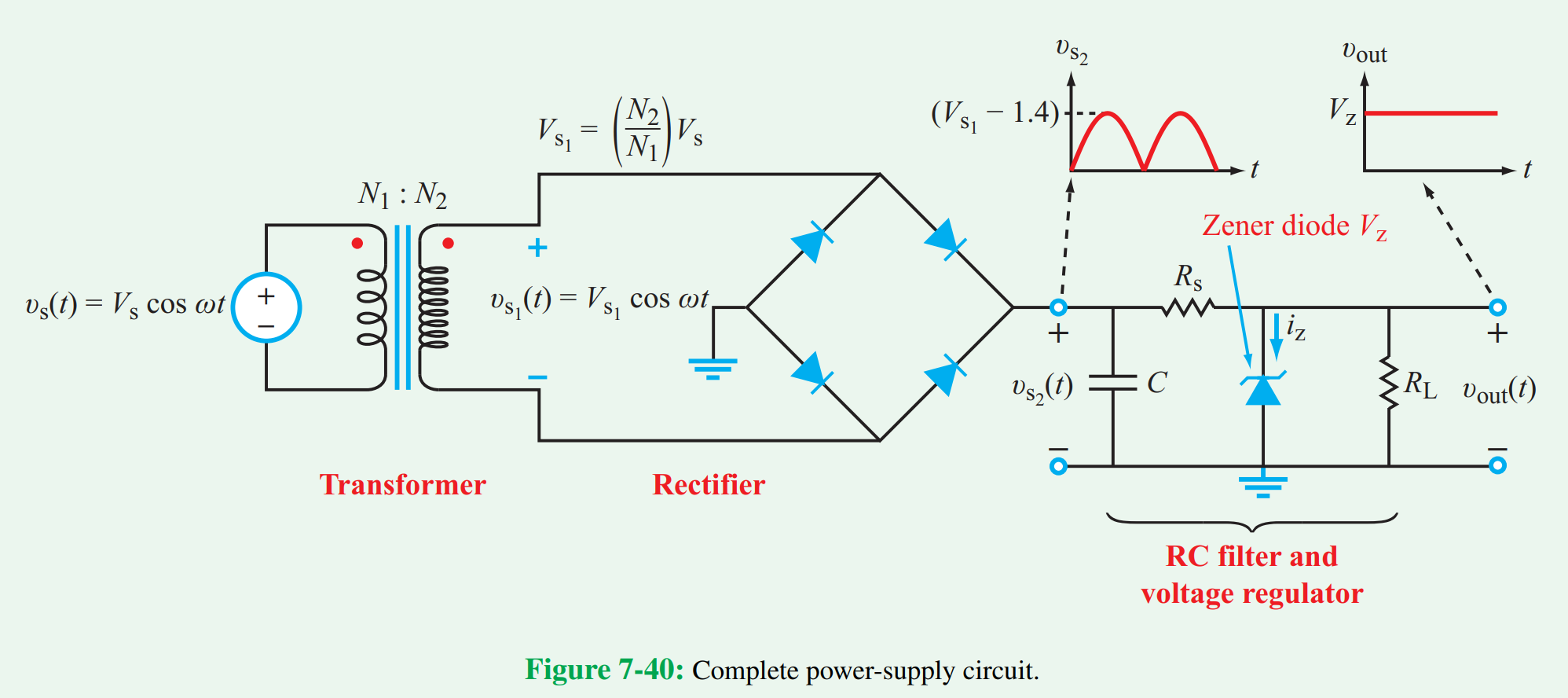

An AC to DC converter can be broken up into multiple stages. An AC input usually needs transformation of the existing power to step up or down voltage to the desired range of operation. In our case, 120V wall power needs to be stepped down by a factor of six to eight before use in the rest of our circuit. This will bring the AC voltage of the secondary between 15 and 20V, ready for rectification from AC to DC. A full bridge rectifier is employed to have current flow in the same direction for each half cycle of AC wave. A rectified wave would then require filter components for reducing voltage swing. Capacitors are employed to store change and mitigate this voltage swing but a separate step for regulation is required. Regulation can be accomplished using multiple methods, primarily using voltage regulator IC’s or Zener diodes in reverse breakdown.

Fig 7-40 of Circuit Analysis and Design 1. A complete circuit of a basic power supply. This design employs a Zener diode regulator.

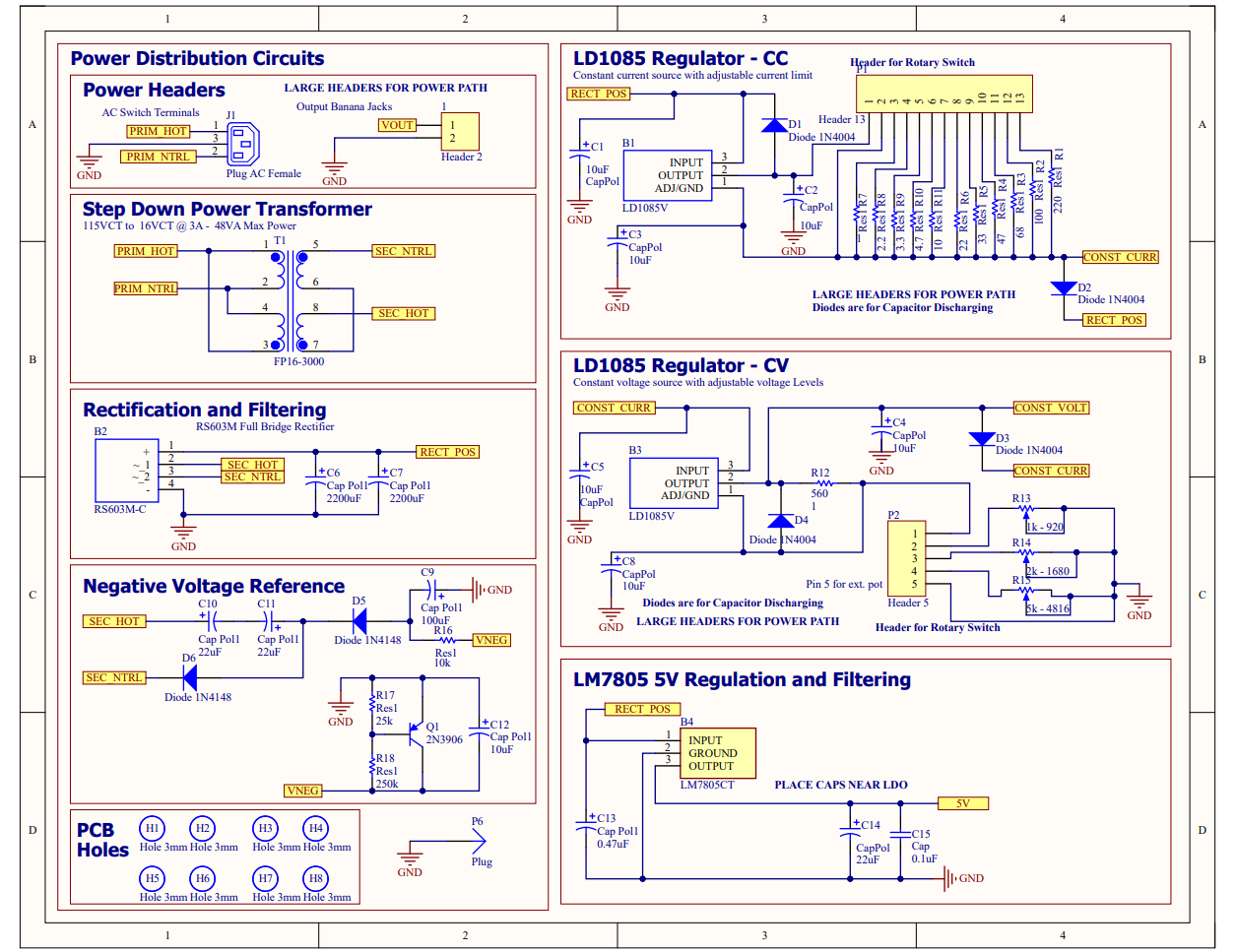

Power Supply Circuit Design

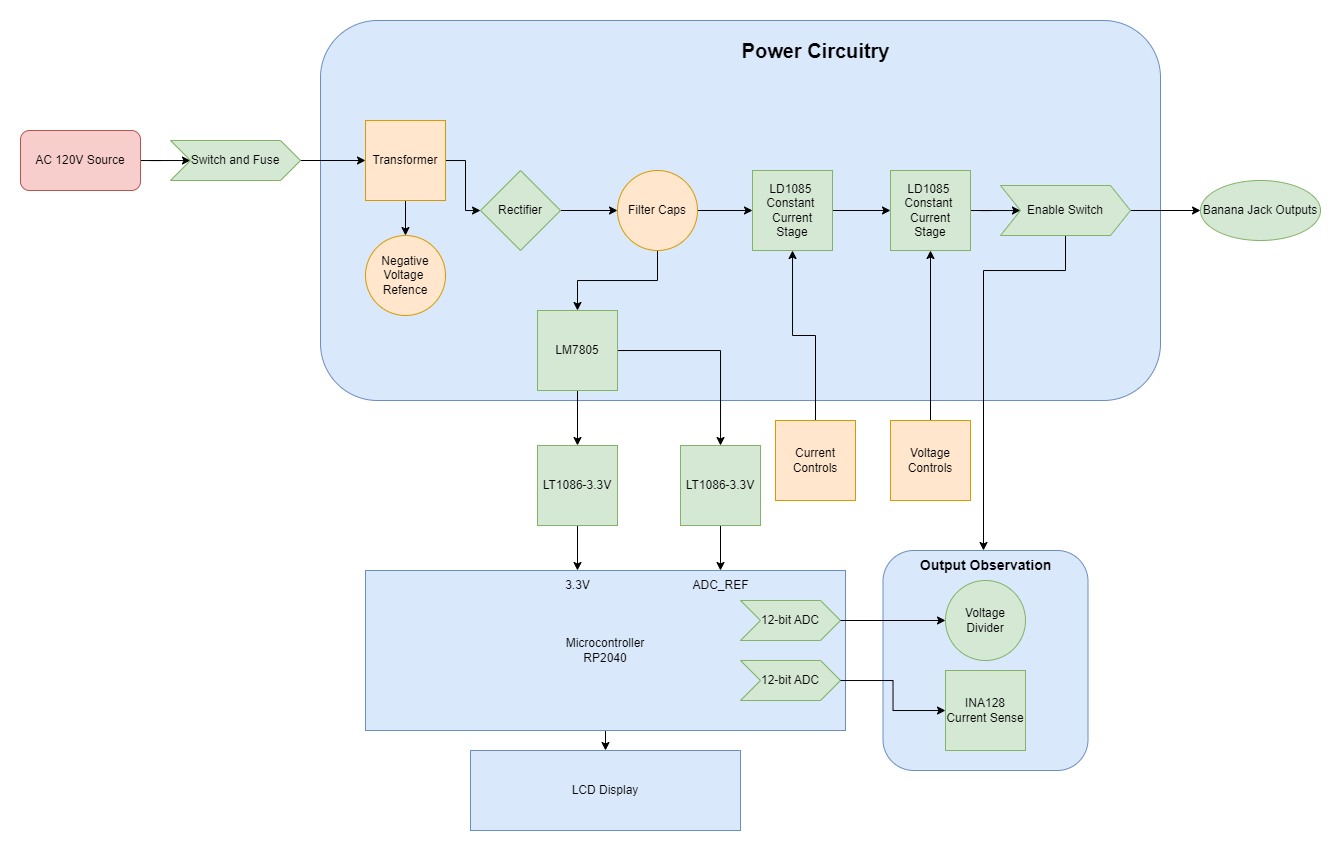

Hardware Block Diagram of the Linear Power Supply.

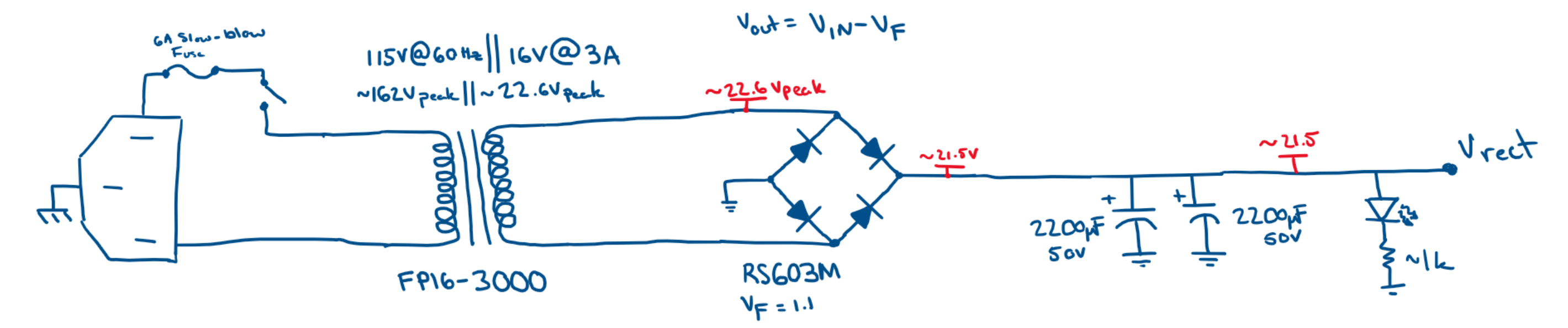

The circuit implements the general systems shown in the block diagram. From the AC outlet, a fuse and switch connect mains voltage to the device for operation. The Flat-Pak 16V transformer (FP16-3000) which can deliver 48VA of power. This device is perhaps one of the most limiting factors of the supply. I anticipate 22.6V peak-to-peak voltage from a 115V AC circuit, which may not be enough for a 20V output after regulation. This will be followed by a RS603M full bridge rectifier, with a forward voltage drop of 1.1V. Two 2200uF capacitors follow the rectifier for filtering, providing a raw DC voltage around 21.5V to the following circuit stages.

Input voltage conditioning Stage.

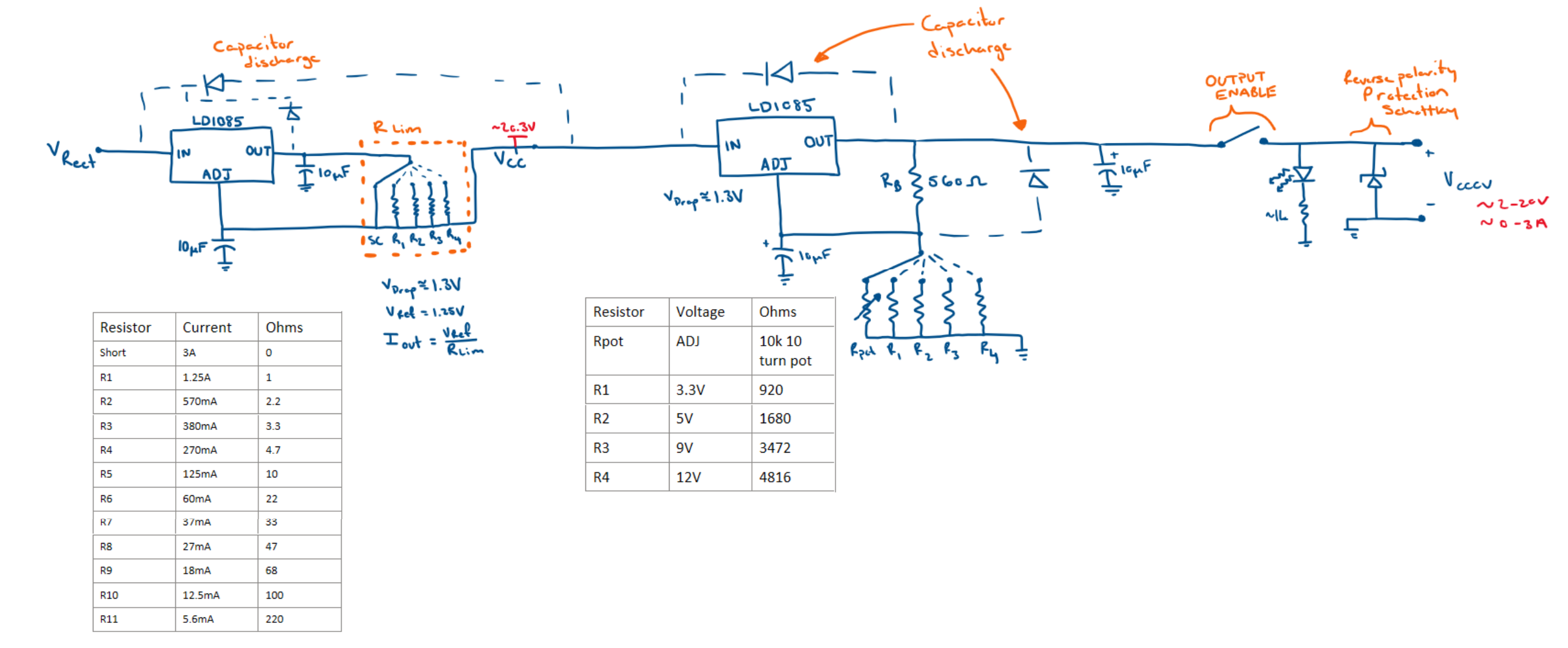

The rectified voltage is passed into the Constant Current Constant Voltage (CCCV) stage for output conditioning. Both stages center around a LD1085 linear regulator IC, which has a 30V rating a can supply 3A of current. The constant current stage uses a selection of switchable series resistances to determine the current limit of following stage. Both output and adjust pins are bypassed for better noise performance but comes at the cost of storing and possibly supplying more energy during a transient spike from the load.

The constant voltage stage allows for switching between a selection of fixed voltage outputs and an adjustable output. Given there is no current limiting occurring, the device should provide 1.25V to about 20V. The output’s upper boundary is limited by the dropout voltage over both linear regulators, forward voltage of the rectifier, output of the transformer, and the AC voltage seen at the plug. The supply should comfortably hit 20V on the output under moderate loads, however bottlenecks may be encountered for worst case scenarios. Again, each terminal of the LD1085 is bypassed for noise performance. Diodes are incorporated for protection purposes on each regulator and will provide a discharge path for capacitors on the adjust and output pins when the device is turned off. An output enable switch, reverse polarity diode, and a LED is employed for output safety and interaction.

Constant Current-Constant Voltage Stage with reverse polarity protection.

Warning

There are some flaws with the constant current circuit as depicted. Decoupling capacitors on the output and adjust pins of the constant current regulator cause current spikes from various operations. the short circuit implemented originally was removed in favor of a 0.33ohm resistor providing the same effect as before. Finally, to reduce transient uncertainty when switching between Rlim resistors, A 10kOhm resistor was added in parallel to Rlim.

If you attempt to recreate this constant current circuit, remove the decoupling capacitors, short circuit condition, and add a high resistance in parallel to Rlim.

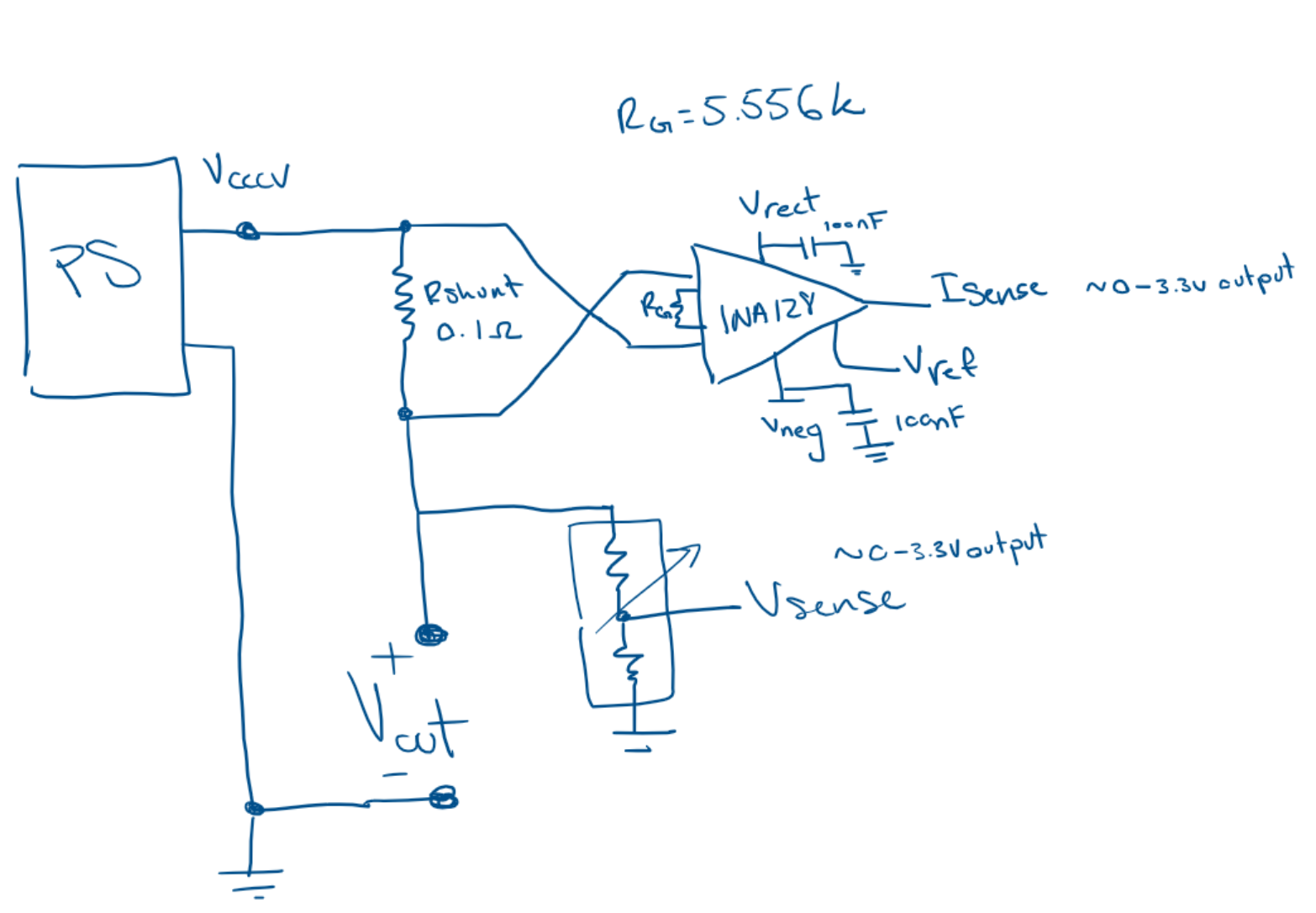

The output of the CCCV then feeds into the measurement circuitry for observation and user interaction. A 0.1 Ohm shunt resistor is added for high side current sensing. This was done with the INA128 which should have no problem observing the dynamic range of the power supply. The current can be no more than 3 amps as set by both the transformer and the regulators. This circuit observe currents in the full operation range and imposes minimal voltage loss on the output. A 100W rated shunt is used for safety during a short circuit condition. A gain of 10 is applied to make the output voltage functionally equivalent to the observed current over the shunt resistor. This means that a 0-3V output can easily be read by a 3.3V ADC. The output voltage is observed through a resistor divider that similarly creates a 0-3V output for ADC readings. The ratio of loss from the divider is inverted and applied back to the sensed ADC value in software to relay the correct output voltage.

Input voltage conditioning Stage.

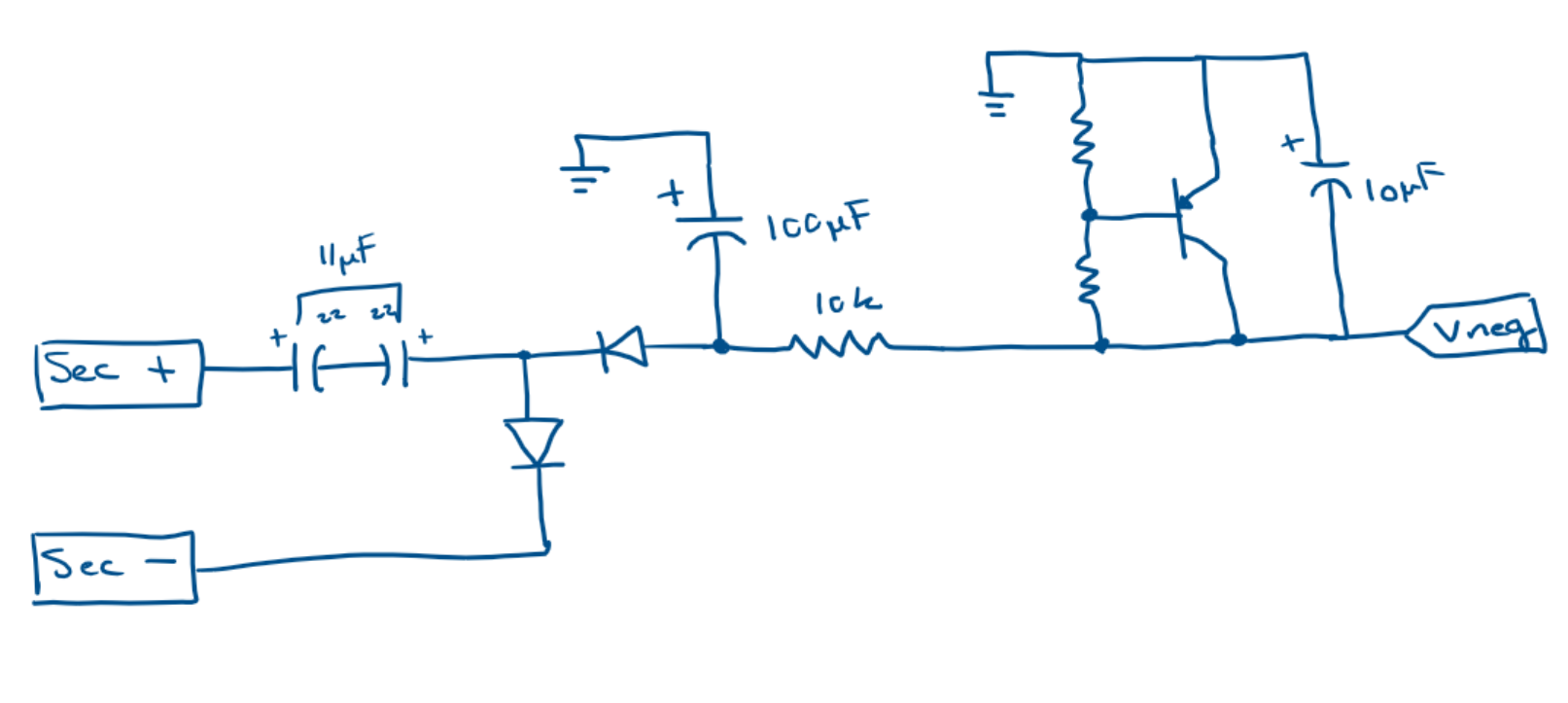

The INA128 used for current readings has a 36V operation range and requires about 2V of offset from each rail to operate effectively. The device will be supplied by both the rectified voltage and a negative reference voltage. This is because the rectified voltage should be approximately 2 to 3V higher than the output of the voltage regulator, giving enough room for higher voltage measurements. However, the device must also output on the 0-3V range. To do this effectively, a negative voltage reference must be made to supply an offset from the lower rail of operation. A negative voltage rail around -3 to -7V is sufficient. This was done using a negative voltage charge pump that feeds a VBE multiplier, giving a nice output reference. The INA128 will only draw about 1mA of current from this rail, so a charge pump is fine for this purpose.

Negative voltage charge pump with Vbe multiplier output.

Pico Setup

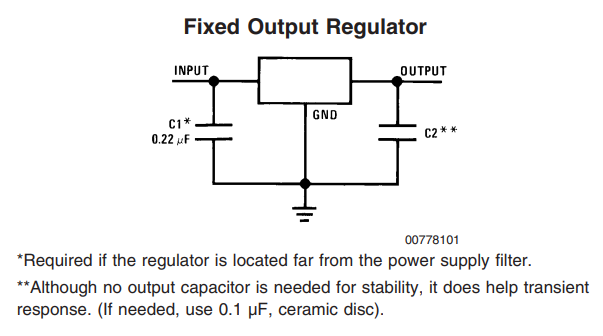

To supply power to the measurement devices, I chose a combination of regulators power the sensor devices. This provided a smooth 5V and 3.3V source for most components, with local decoupling capacitors where needed. The LM7805 is a prime candidate for 5V regulation as its implementation is simple, only requiring two capacitors on the Vin and Vout. The 7805 is also tolerant to the range of voltage seen after rectification.

Fixed Output Regulator configuration for an LM7805.

In addition to the 5V source, I powered the Raspberry Pico via 3.3V regulators. Two 3.3V rails were also developed using LT1086 regulators, also in a fixed configuration. One regulator was connected directly to the 3.3V rail, while the other was connected to the ADC reference.

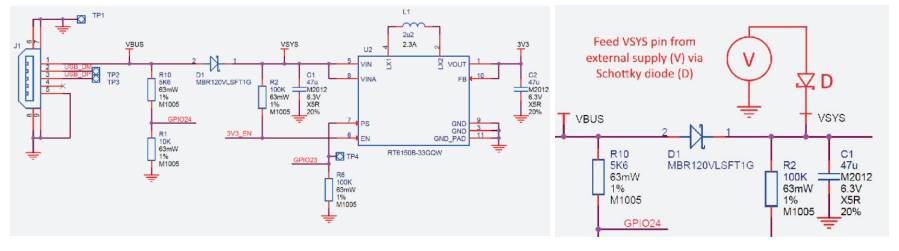

Pico Power-chain.

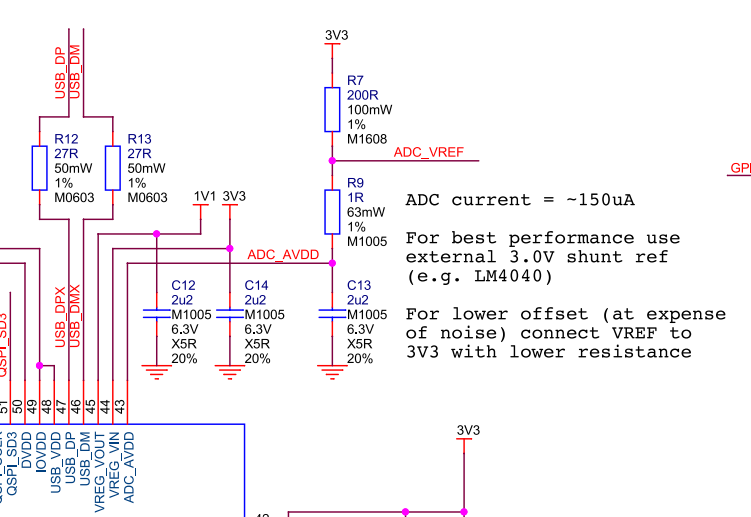

ADC Configuration

Pico ADC reference circuit.

For this project, I did everything I could to isolate the ADC reference for the best possible readings. Essentially, I have added a separate 3.3V linear regulator specifically for the ADC reference. To use this reference voltage without digital operation or SMPS noise, I have removed the R7 resistor that connects the Pico’s 3.3V source to the ADC reference. This method heavily isolates the ADC reference. It is potentially overkill, but I was interested in seeing how the device would perform.

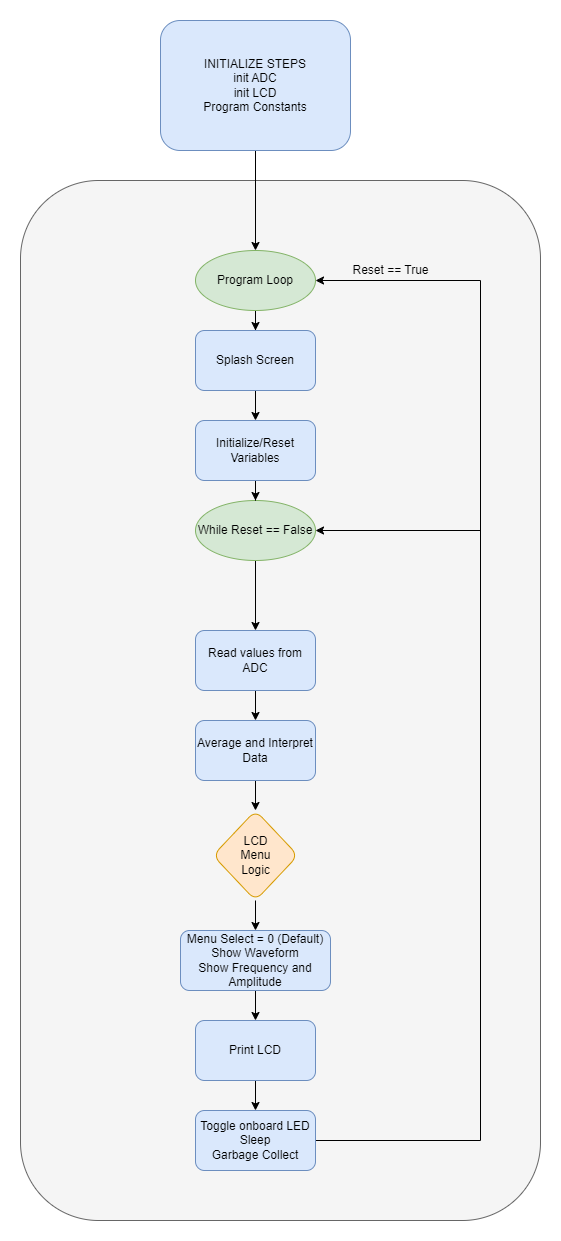

Pico Software

Hardware Block Diagram of the Linear Power Supply.

The Pico has a relatively simple program loop, A few systems such as the LCD and ADC are initialized on startup, then continuous readings from both ADC channels are taken for interpretation. Each channel has offset removed, becomes averaged over several samples, and scaled if necessary. Then the data is printed onto the LCD screen for interpretation. There are a few edge cases regarding the output being off, an open circuit, and a short circuit. In these situations, the LCD relays the situation to the user based on interpreted ADC data.

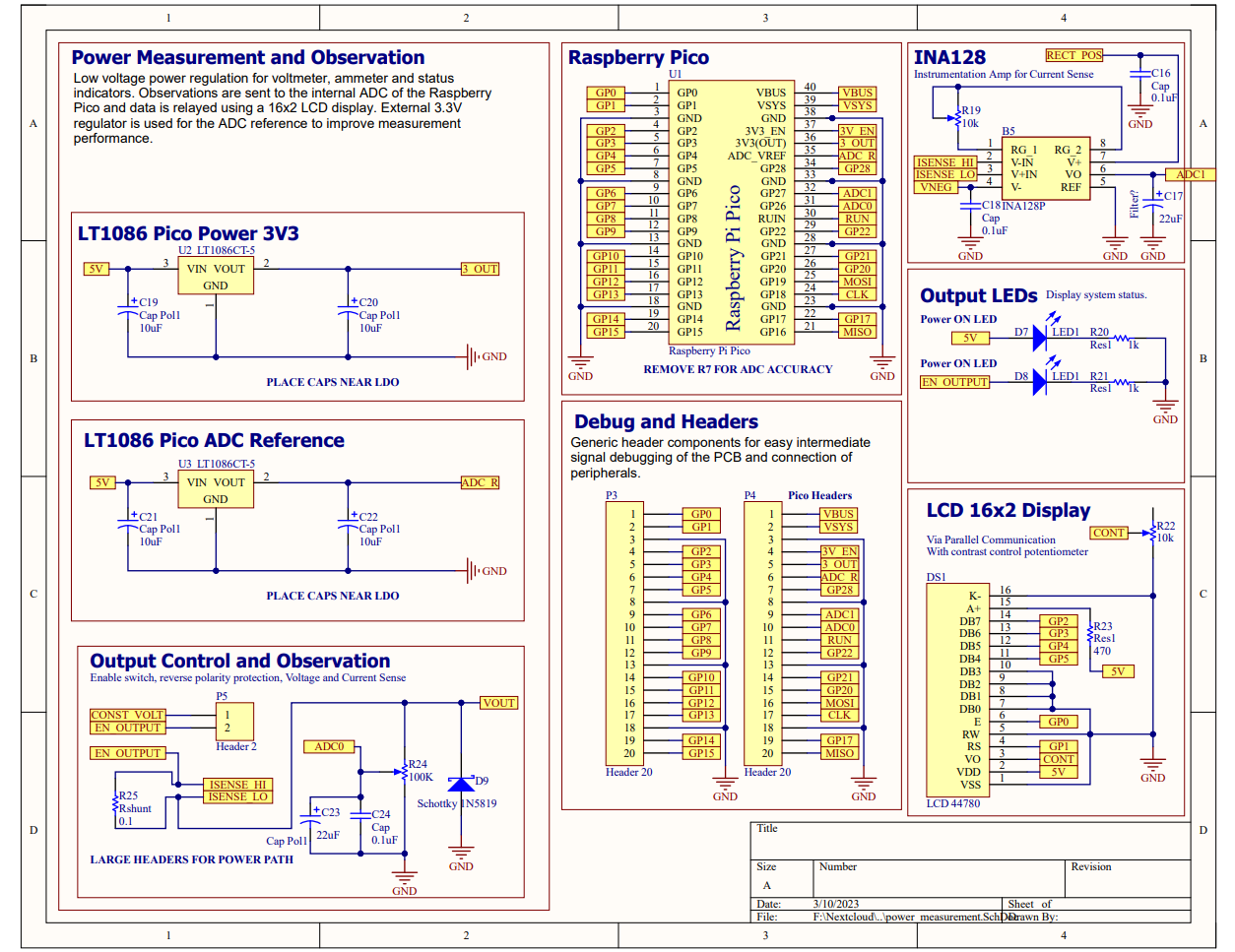

Schematic and PCB Design

All previously mentioned components must be compiled into a schematic design for wiring structure and PCB design. Bypass and decoupling capacitors are added to the board for several reasons. First, capacitors can be used on power headers to avoid voltage spikes and removing AC ripple on DC power. Small ceramic caps offer low series resistance and react fast but have a difficult time dealing with substantial amounts of charge over long periods. Polarized electrolytic capacitors usually have a much higher capacitance, and in conjunction with smaller ceramic capacitors, effectively clean DC voltage. In larger schematics and PCB’s, we are not always able to position circuits near bypass capacitors. Therefore, small decoupling capacitors are recommended for placement near a circuit subsection to help clean AC ripple from DC voltages.

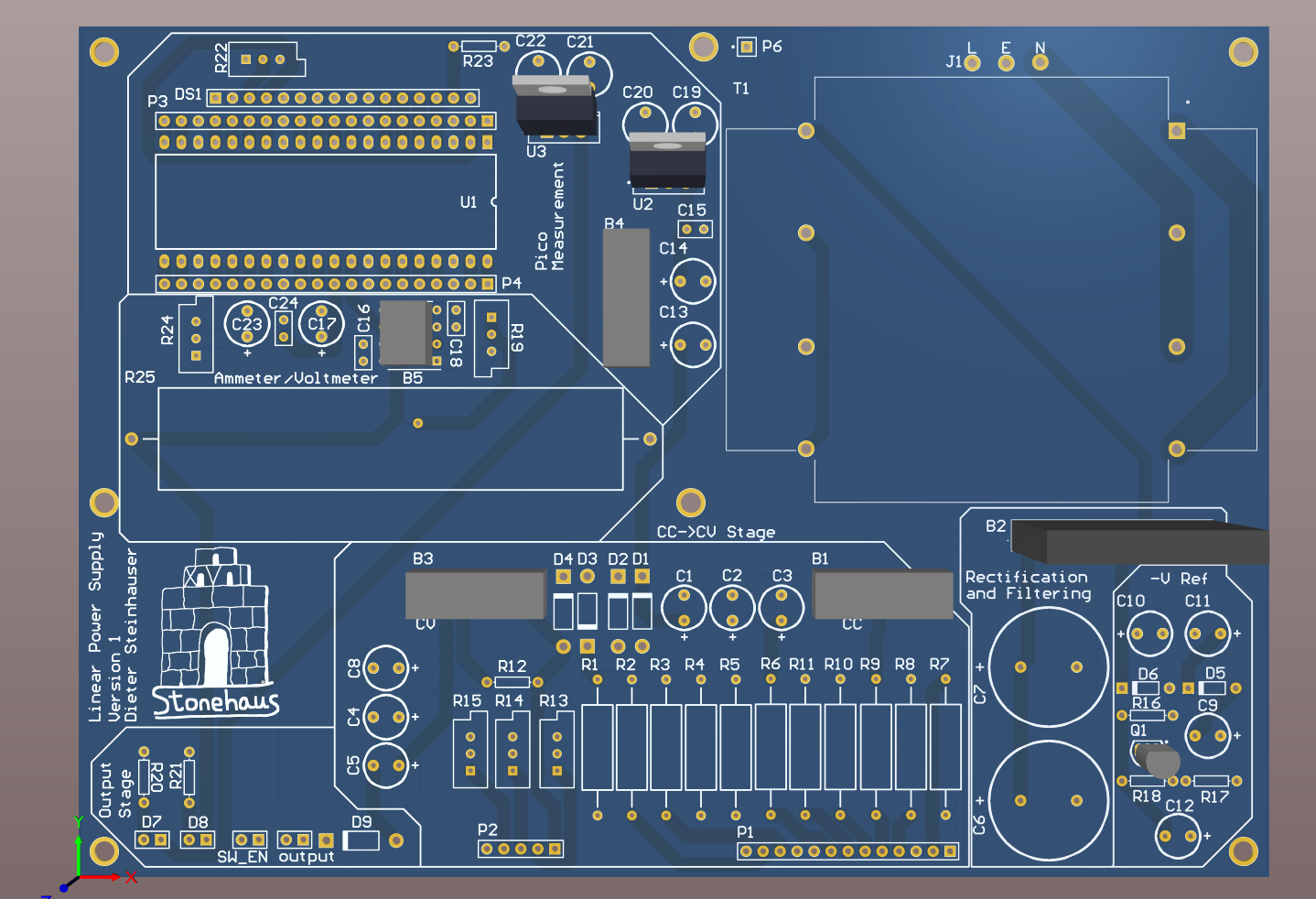

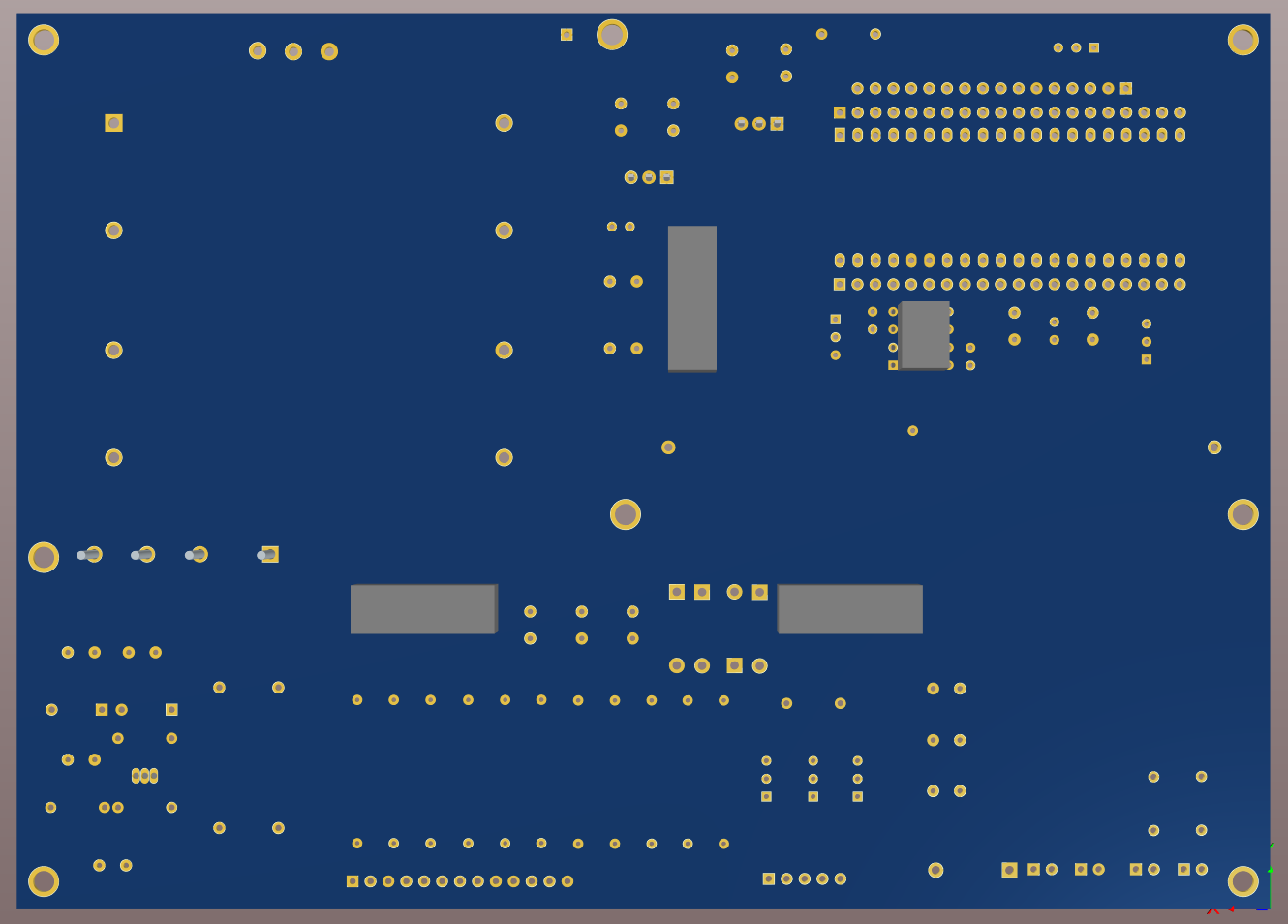

Once the schematic was populated with all necessary circuit components, the PCB was updated with all schematic components for board layout. A general layout of parts was done before resizing the board outline to find the most effective use of space. When all components have found their relative placement, routing traces for components using auto-routing tools or manually is required. I chose to auto-route, followed with manual edits to correct some trace routes. I found 100mil routes were sufficient for this circuit. Copper pours are also recommended for adding a ground layer to the PCB, further simplifying routing design.

Power Supply schematic page 1 of 2.

Power Supply schematic page 2 of 2.

Top side of Power Supply PCB layout.

Bottom side of Power Supply PCB layout.

Bill Of Materials

Results

The schematic of the circuit and PCB turned out fine, with a few errors that were fixable. The assembled PCB was easy to debug because of its plentiful headers employed in the diagram. Thankfully, there were no design breaking errors in this circuit, and most components worked immediately after installation.

Power Supply Board.

Flaws and Oversights

There were a few things that I messed up in designing the board, but acknowledging them is a good practice as lessons are learned and further revisions could be optimized. In terms of some minor design issues, I went overkill on a series of parts. the Raspberry Pico’s powerchain is excessive but works wonderfully. I could have easily removed one of the 3.3V regulators and relied on the Pico’s internal SMPS fed from the 7805 for operation. This doesn’t affect the ADC since the reference is isolated from removing the R7 resistor. Using a linear regulator for an ADC reference was also overkill, and a LM385, TL431, or some other voltage reference could have been used to cut costs a bit. That being said, this powerchain worked wonderfully and provided very clean measurements.

In addition, I completely over-specified the shunt resistor needed for current sensing. I employed a 100W resistor thinking that the total power of the device could deliver 20V/3A = 60W during a short circuit condition. However, I neglected to see that the entire short circuit wire would act as a resistor and that the power dissipated on a resistance is equal to I*I*R or about 1W in my design. this is without mentioning any limiting or thermal shutdown that would occur.

Some more serious design errors included incorrectly wiring the instrumentation amplifier. This caused the device to read negative values and therefore send useless data to the ADC for current readings. Since I chose to use an IC riser, This was easily worked around using some wire wrapping. Some header ports were also too small for wires and made connecting the front panel difficult. The most egregious error was from designing the constant current regulator with decoupling capacitors and without a parallel limit resistor. These too factors led to the destruction of a handful of regulator IC’s from current spikes.

Conclusion

Overall, This project has been insightful and a useful addition to my workbench. While there were some design faults, all errors were fixable and operation has not been impacted. Creating a linear power supply is a great way to introduce power electronics to engineers and provide utility to the engineer for future projects. This device performed well at providing power and realistic measurements to the user.

Appendix

main.py

1# ----------------------------------------- 2# NOTES 3# ----------------------------------------- 4""" 5Dieter Steinhauser 612/2022 7PicoPAD Test Script 8 9""" 10 11# ----------------------------------------- 12# IMPORTS 13# ----------------------------------------- 14 15from LCD import * 16# import _thread 17from utime import sleep, sleep_ms, sleep_us, ticks_ms 18from machine import Pin, Timer, ADC, freq 19# import gc 20 21# ----------------------------------------- 22# CONSTANTS/VARIABLES 23# ----------------------------------------- 24 25# ------------------ 26REFRESH_RATE = 360 # Frequency in Hz 27REFRESH_PERIOD = int((1 / REFRESH_RATE) * 1000) # delay in milliseconds 28 29# ------------------ 30UPY_BIT_RES = 16 31ADC_REF = 3.3 32VOLT_PER_BIT = ADC_REF / (2**UPY_BIT_RES) # ADC recieves in 2 byte packets and micropython automagically fixes it. 33 34# ------------------ 35DAC_REF = 5.0 36DC_OFFSET = 0 37DC_OFFSET_RES = int((DC_OFFSET / DAC_REF) * (2**UPY_BIT_RES)) 38 39# ------------------ 40FREQ_MAX = 160 41FREQ_MIN = 10 42AMP_MAX = DAC_REF 43AMP_MIN = 0 44 45MAX_DIST_US0 = 50 46MAX_DIST_US1 = 20 47 48 49# ------------------------------------------------------------- 50# INITIALIZATION 51# ------------------------------------------------------------- 52 53# ----------------------------------------- 54# SYSTEM CLOCK 55# ----------------------------------------- 56 57UNDERCLOCK = 30_000_000 58DEFAULT_SYS_CLK = 125_000_000 59STABLE_OVERCLOCK = 270_000_000 60 61# Pico can go up to 270MHz before needing to flash to the eeprom directly. 62system_clock = DEFAULT_SYS_CLK 63 64# if the system clock is not the default, apply the clock speed. 65if system_clock != DEFAULT_SYS_CLK: 66 freq(system_clock) 67 68# print(f'Clock: {freq()/1e6}MHz') 69 70# ----------------------------------------- 71# PINOUT 72# ----------------------------------------- 73 74# LCD Pins handled in LCD.py 75# ---------------------------- 76# EN = Pin(0, Pin.OUT) 77# RS = Pin(1, Pin.OUT) 78# D7 = Pin(2, Pin.OUT) 79# D6 = Pin(3, Pin.OUT) 80# D5 = Pin(4, Pin.OUT) 81# D4 = Pin(5, Pin.OUT) 82 83# Ultrasonic sensor pins handled in sensors.py 84# ---------------------------- 85# us0_trig = Pin(6, Pin.OUT) 86# us0_echo = Pin(7, Pin.IN) 87# us1_trig = Pin(8, Pin.OUT) 88# us1_echo = Pin(9, Pin.IN) 89 90# Switches 91# ---------------------------- 92# sw0 = Pin(10, Pin.IN, Pin.PULL_DOWN) 93# sw1 = Pin(11, Pin.IN, Pin.PULL_DOWN) 94# sw2 = Pin(12, Pin.IN, Pin.PULL_DOWN) 95# sw3 = Pin(13, Pin.IN, Pin.PULL_DOWN) 96# switch_pins = [sw0, sw1, sw2, sw3] 97 98# LEDs 99# ---------------------------- 100# led0 = Pin(14, Pin.OUT) 101# led1 = Pin(15, Pin.OUT) 102led_onboard = Pin(25, Pin.OUT) 103output_en = Pin(16, Pin.OUT) 104# led_pins = [led0, led1, led_onboard] 105 106# SPI handled by the Hardware in spi_config.py 107# ---------------------------- 108# miso = Pin(16, Pin.IN) 109# cs = Pin(17, Pin.OUT, value=1) 110# mosi = Pin(18, Pin.OUT) 111# sck = Pin(19, Pin.OUT) 112 113# Buttons 114# ---------------------------- 115# button0 = Pin(20, Pin.IN) 116# button1 = Pin(21, Pin.IN) 117# button2 = Pin(22, Pin.IN) 118# button3 = Pin(28, Pin.IN) 119# button_pins = [button0, button1, button2, button3] 120 121# ADC 122# ---------------------------- 123# adc0 = ADC(26) # Connect to GP26, which is channel 0 124# adc1 = ADC(27) # Connect to GP27, which is channel 1 125 126# ----------------------------------------- 127# LCD 128# ----------------------------------------- 129lcd_init() 130lcd_clear() 131# lcd_cursor_on() 132# lcd_cursor_blink() 133# ----------------------------------------- 134# ADC 135# ----------------------------------------- 136adc1 = ADC(26) # Connect to GP26, which is channel 0 137adc0 = ADC(27) # Connect to GP27, which is channel 1 138# adc2 = machine.ADC(28) # Connect to GP28, which is channel 2 139# adc_reading = adc0.read_u16() * VOLT_PER_BIT # read and report the ADC reading 140 141# ----------------------------------------- 142# SD CARD VIA SPI 143# ----------------------------------------- 144# 145# import sdcard 146# import os 147# import uos 148# 149# # Assign chip select (CS) pin (and start it high) 150# cs = Pin(20, machine.Pin.OUT) 151# 152# # Intialize SPI peripheral (start with 1 MHz) 153# spi = machine.SPI(0, 154# baudrate=1000000, 155# polarity=0, 156# phase=0, 157# bits=8, 158# firstbit=machine.SPI.MSB, 159# sck=Pin(18), 160# mosi=Pin(19), 161# miso=Pin(16)) 162# 163# # Initialize SD card 164# sd = sdcard.SDCard(spi, cs) 165# 166# vfs = uos.VfsFat(sd) 167# uos.mount(vfs, "/sd") 168# 169# # Create a file and write something to it 170# file = open("/sd/test01.txt", "w") 171# 172# with open("/sd/test01.txt", "w") as file: 173# file.write("Hello, SD World!\r\n") 174# file.write("This is a test\r\n") 175# 176# # Open the file we just created and read from it 177# with open("/sd/test01.txt", "r") as file: 178# data = file.read() 179# print(data) 180 181# ----------------------------------------- 182# PROCESS 1: IO 183# ----------------------------------------- 184 185while True: 186 187 splash = True 188 # Display the splash screen on startup. 189 if splash is True: 190 led_onboard(1) 191 lcd_puts(f'Linear Supply ') 192 lcd_goto(0,1) 193 lcd_puts(f'20V/3A Dieter S.') 194 sleep(2) 195 lcd_home() 196 lcd_clear() 197 led_onboard.toggle() 198 199 list_length = 100 200 counter = 0 201 current_list = [] 202 voltage_list = [] 203 while True: 204 205 # read ADC 206 # ----------------------------------------- 207 208 adc0_reading = (adc0.read_u16() * VOLT_PER_BIT) 209 adc1_reading = (adc1.read_u16() * VOLT_PER_BIT) 210 211 voltage = (adc1_reading - 0.010) * 7.2962 212 current = (adc0_reading - 0.010) 213 214 current_list.append(current) 215 voltage_list.append(voltage) 216 counter += 1 217 218 if counter == list_length: 219 220 221 current = sum(current_list)/ len(current_list) 222 voltage = sum(voltage_list)/ len(voltage_list) 223 224 current = round(current, 3) 225 voltage = round(voltage, 3) 226 227 if current <= 0: 228 current = 0 229 230 if voltage < 0.9: 231 voltage = 0 232 current = 0 233 output_en(0) 234 else: 235 output_en(1) 236 237 counter = 0 238 current_list = [] 239 voltage_list = [] 240 241 lcd_home() 242 lcd_puts(f'A: {current}A ') 243 lcd_goto(0,1) 244 lcd_puts(f'V: {voltage}V ') 245 246 # toggle onboard LED for System speed status and refresh delay 247 # ----------------------------------------- 248 led_onboard.toggle() 249 utime.sleep_ms(REFRESH_PERIOD) 250 # gc.collect() 251 252 253 254