Ultrasonic Theremin - Junior Design

Date: 11/2022

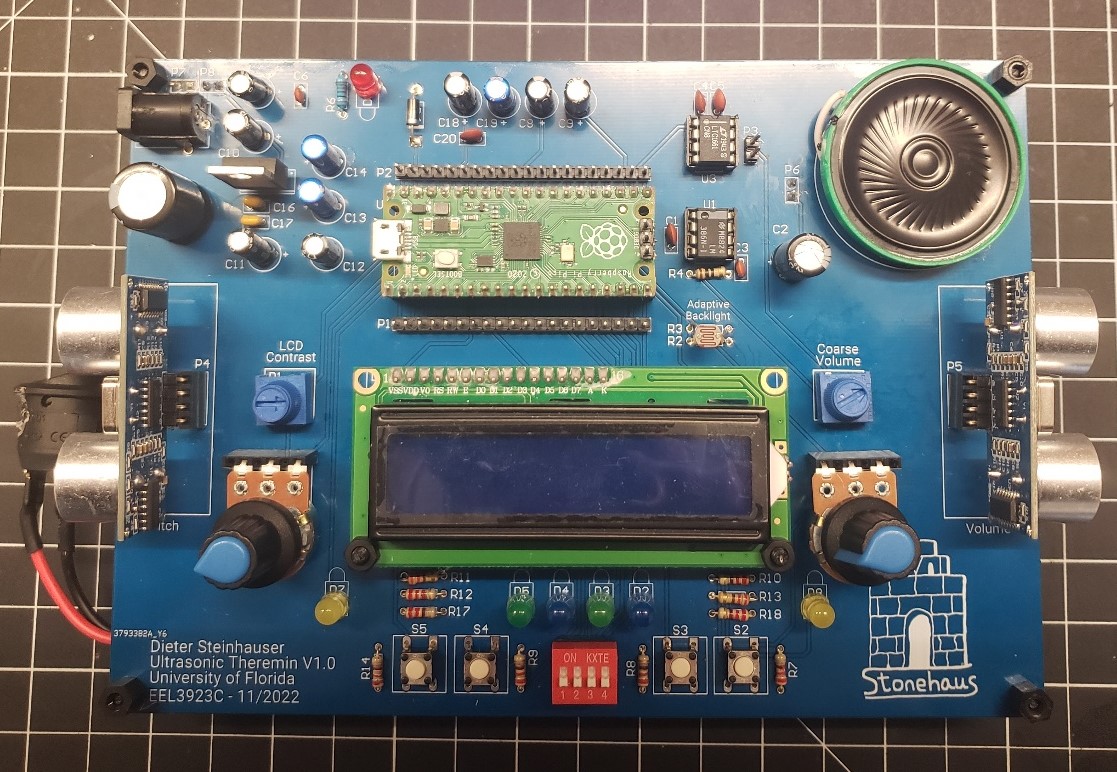

Ultrasonic Theremin in its case.

Introduction

The Theremin is a musical instrument designed by Leon Theremin in 1928. The device operates using two antennas relying on capacitor physics, which sense the position of the operator’s hands. One antenna influences the output frequency of the note, while the other influences the volume of the note. While the original theremin operates on a series of analog systems, I intend to implement similar systems in the digital domain by using the ultrasonic sensors to determine distance between the instrument and the operator’s hands. The digital and analog inputs will augment a waveform generator, which creates an audio signal according to the user’s movements, creating a digital instrument.

Methods

Project Overview

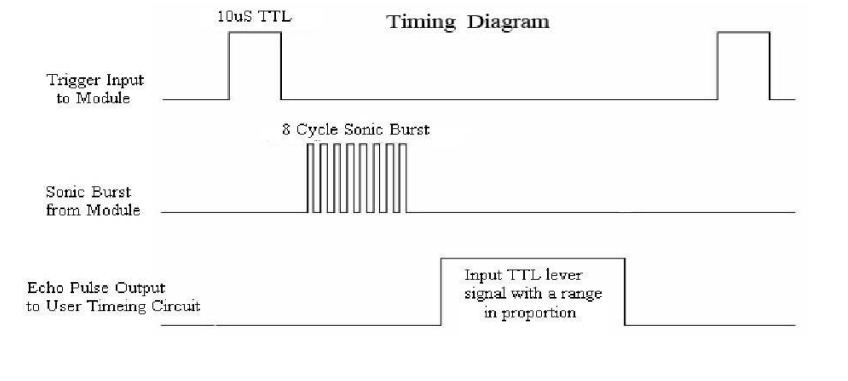

The raspberry Pico interfaces with multiple components and generates waveform functions for audio output. Ultrasonic sensors detect distance from the users’ hands for frequency determination. Status of the device is displayed on an LCD. Switches and Buttons are available on the device for interaction, selecting output waveforms and other menu options. Potentiometers are connected to the Pico ADC for controlling the upper and lower boundaries of the frequency range. LED’s will assist by lighting up when a boundary is hit.

All generated waveforms are sent to the DAC via SPI and then to the LM386 audio amplifier, which drives the 8-ohm speaker. Everything can be powered using a 9V battery or adapter, as 5V is generated using the LM2940 LDO. This powers most standalone components, including the Pico. The SMPS on the Pico also generates 3.3V and is filtered for usage in GPIO.

Pico Overview

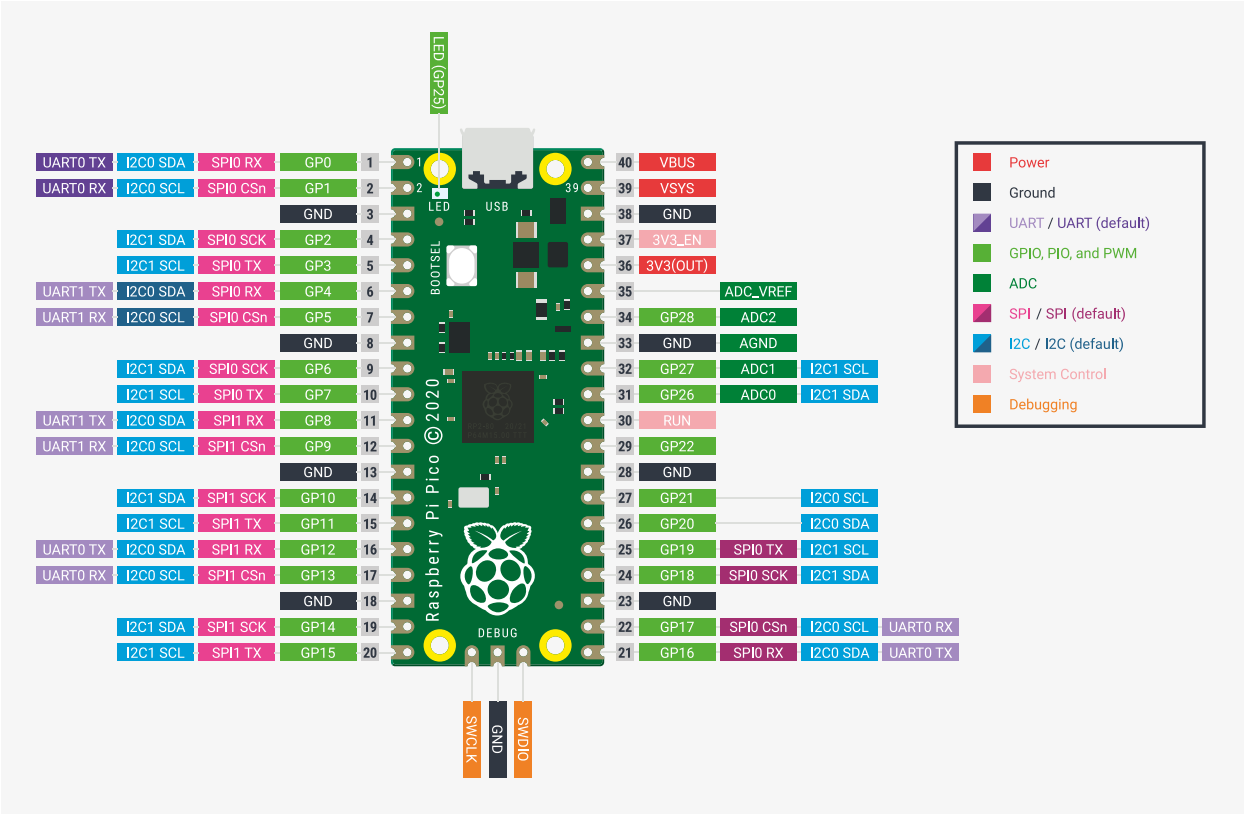

The Raspberry Pico is a development board with an RP2040 microcontroller chip. It has 264KB of SRAM and 2MB of flash memory. Development for the Pico is versatile as the platform capable of being programmed in MicroPython, CPython, C, and Rust 13. The Pico has a dual core processor capable of 133MHz clock speed, set to 125MHz out of the box 15. There are 40 GPIO pins on the board, with SPI, I2C, and UART communication capability. The Pico comes equip with a 12-bit 500ksps ADC with 5 channels total. One channel is configured to an RP2040 internal temperature sensor, and three are tied to GPIO pins on the Pico 14. The Pico also has a timer with four alarms, a Real-Time-Counter (RTC), and sixteen Pulse-Width Modulation (PWM) channels

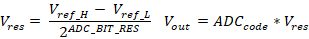

ADC Theory

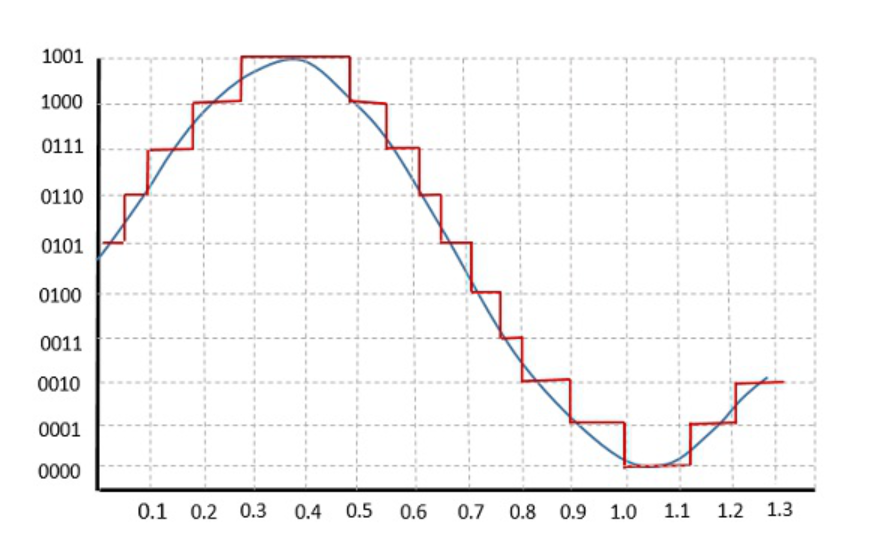

Analog to Digital Converters are the primary method of capturing analog data using a microcontroller. ADC’s capture analog signals such as sound or light waveforms and convert them to a digital signal for processing of information. An ADC takes continuous magnitude data from a continuous time domain into discrete magnitude data in a discrete time domain 3. The conversion quantizes the signal based on the resolution, reference voltages, and sample rate of the ADC, introducing small errors into the signal as noise.

Quantization of an Analog to Digital Converter on a sine wave.

Resolution and reference voltages of an ADC produces quantization errors within the amplitude domain of a signal, where the sample rate of an ADC produces quantization errors within the time domain. Resolution gives the number of discrete values an ADC can produce, where the reference voltages provide the span of voltages the ADC can receive as a signal. Ground is often defaulted to the lower reference voltage to simplify ADC implementation. As a result, the voltage resolution in volts per bit is given as the span between the reference voltages divided by the number of discrete values the ADC resolution can produce. The digital code made by the ADC multiplied by the voltage resolution of the ADC will return the voltage recorded by the ADC. Quantization produces rounding errors in the approximation of the analog voltage, which is worsened by noise and jitter that exists on the signal prior to the ADC conversion. Signal noise can significantly reduce the effective number of bits to which an ADC is accurate.

ADC formulas.

Sample rate of an ADC produces quantization errors within the time domain of the signal. The sampling rate of an ADC should ideally greater than twice the highest frequency being recorded, otherwise aliasing will occur. Aliasing can also be mitigated by adding a low-pass filter to the ADC input, removing frequencies above half of the sampling frequency. Oversampling is also commonly employed as it can reduce noise and improve bit-depth.

ADC Configuration

Since the ADC in on the Raspberry Pico, initial setup of the ADC can easily be achieved using the ADC section of the Pico Software Development Kit (SDK) 14. This provides the engineer with a simple and straightforward introduction on taking ADC readings. However, the 12-bit ADC onboard the Pico is not great by any means. This is due to the switching power regulator on the Pico. As a result of switching signal noise, the onboard voltage reference for the ADC is setup in poor conditions. The ADC has a 30mV offset and its signal is quite noisy 13. The datasheet gives suggestions on improvement of the ADC readings. An External reference voltage may be used, the R7 resistor can be removed, or issues can be mitigated in averaging and offset code. I chose a different route entirely, by adding bypass capacitors to the reference voltage and ADC input pins for filtering and smoothing. This is enough for the applications of this project.

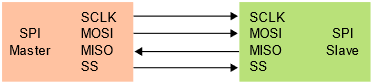

SPI Theory

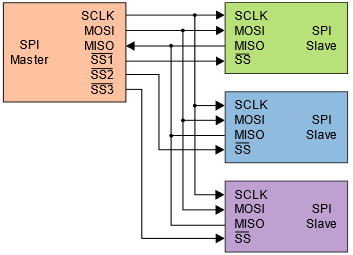

SPI is a full-duplex serial communication protocol that was created by Motorola in the 1980’s for high-speed communication in embedded systems 16. The SPI protocol consists of a single master device and one or many slave devices. For a simple two device system, A clock (SCLK), a chip select (CS), and two data lines (MOSI, MISO) are employed. MOSI is the data transmitted from the master device, while MISO is the data received from the master device.

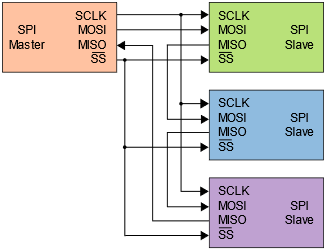

SPI can incorporate multiple slave devices by connecting data and clock lines, individually accessing a slave device by using a dedicated chip select line for each device as seen in figure 5. This can become GPIO intensive as the number of pins needed on the master device will increase with each additional slave device. Alternatively, SPI devices can work cooperatively by tying all chip selects to the same line as seen in figure 6. This works well if data does not need to be returned from the slave devices and the slave devices are intended to have the same output.

Figure 5: SPI independent configuration 16. |

Figure 6: SPI daisy-chained configuration 16. |

SPI transmits and receives data simultaneously in both directions, making the communication full duplex in design. SPI also uses GPIO for addressing a chip instead of transmitting addresses over the data lines commonly seen in I2C. Because of the full duplex data transmission and GPIO addressing, SPI has very high transmission speeds, but can become GPIO intensive. In practice, the maximum clock speeds of a SPI configuration depend highly on the connected devices and their method of connection. Finally, the SPI protocol is highly configurable in that the clock polarity and phase can be configured. This is also highly dependent on connected devices and should be considered when creating a two-device or multi-device system. In terms of using SPI on the Pico, A clock at or below 1MHz is best for breadboarding and flywire use.

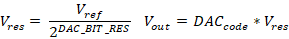

DAC Theory

A Digital to Analog Converter operates on much of the same principles of an ADC but in reverse. DAC’s take a digital code that is within the resolution range of the device and output an analog waveform. Uses for DAC’s are often found in creating audio and video signals 4. A DAC will have a singular or pair of voltage references and a bit resolution for characterizing the precision and range of the output waveform. An output voltage can be calculated by dividing a given code by the number of discrete values the DAC can produce. This is then multiplied by the reference voltage to return the ideal output voltage.

DAC formulas.

DAC’s have some non-idealities in the form of differential and integral non-linearity, which characterize the difference between two adjacent code values and the difference in the transfer characteristic, respectively.

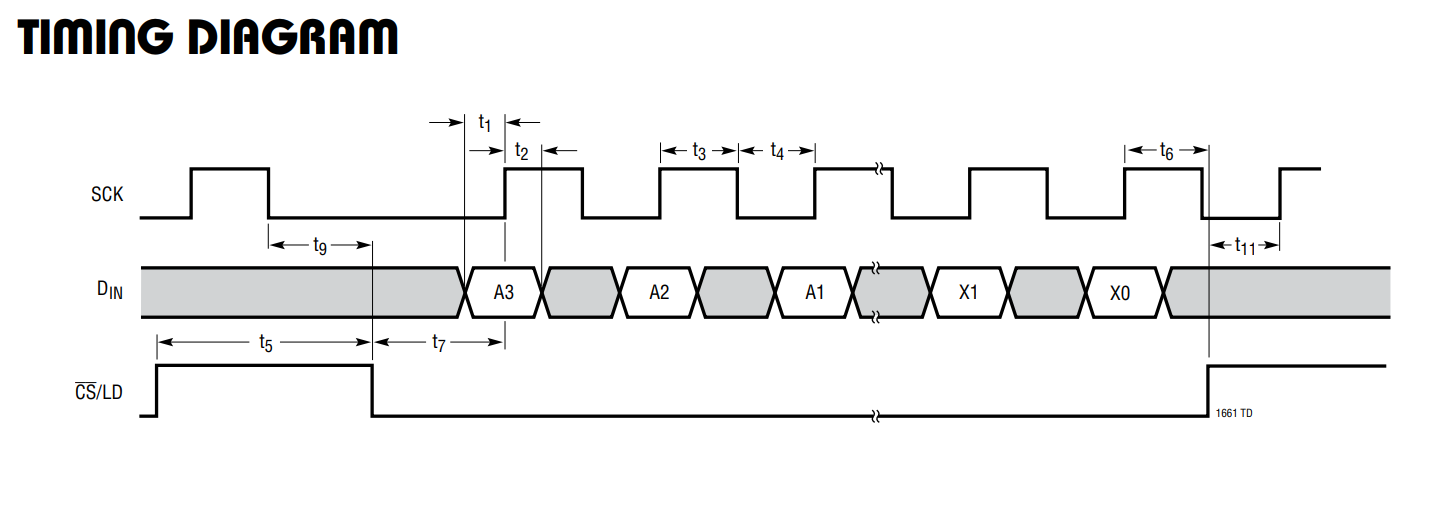

DAC Configuration

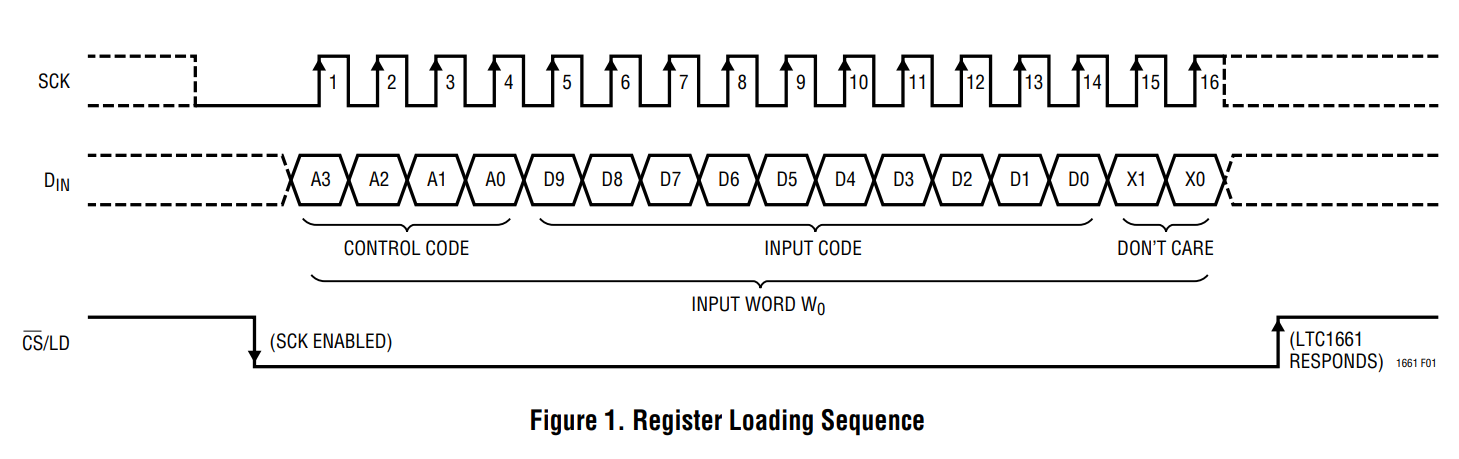

The LTC1661 from Linear Technology hosts two 10-bit DAC’s that are addressable via SPI 3. Communication is configured with the SPI clock idling low and capturing data on the rising edge of the clock. Simple initialization of SPI on the Pico can be seen chapter 3.7 the MicroPython SDK 14. For an in-depth approach to SPI initialization and communication on the Pico, the MicroPython documentation for the SPI module proved insightful 12. The maximum baud rate of the LTC1661 is 10MHz 10. I employed a baud rate of no larger than 8MHz to avoid data corruption on the breadboard. However, small distances of SPI connections on the final PCB make higher speeds possible. The default SPI pins of the Pico were employed, located the bottom right corner of the Pico Pinout 13.

Communication with this DAC is slightly more complicated due to the 10-bit resolution associated with the device. Commanding the device to write to its internal register and Update is the primary functionality desired for this module. Knowing this, the commands 0x9 or 0xA would be applicable for continuously changing voltage on output A and B respectively 10

In our program, we must parse the data for every transmission so that a word packet sent will have the format seen in figure 9. The LTC1661 sends the command, then splits the data bits between the two bytes, followed by don’t cares to fill the word packet. In an 8-, 12-, or 16-bit DAC, less bit manipulation is required.

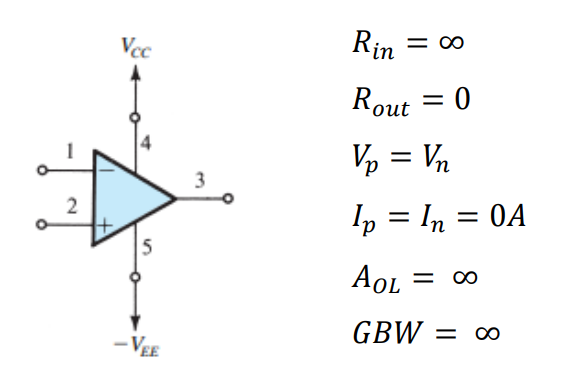

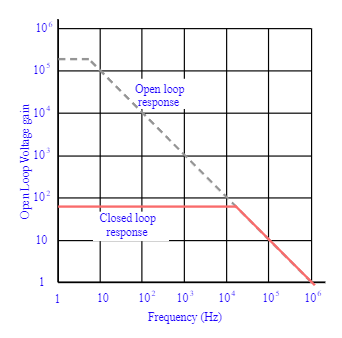

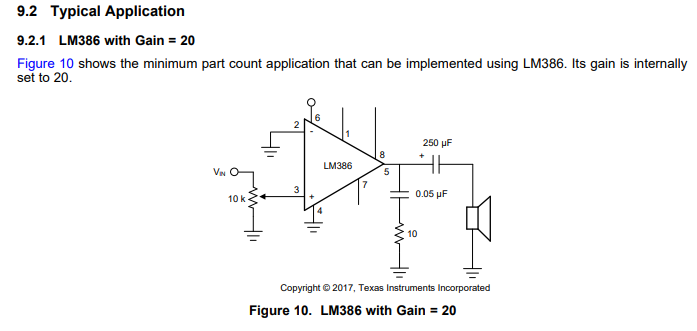

Operational Amplifier Theory

Operational Amplifiers (Op-Amps) are high-gain voltage amplifiers with differential input and a single voltage output. Op-Amps typically have five terminals: An inverting input, non-inverting input, an upper supply, a lower supply, and an output. An ideal Op-Amp has an infinite input resistance and zero output resistance. As a result, input terminals see zero current. Input terminals also see equivalent voltages. Lastly, ideal op-amps experience infinite open-loop gain and infinite Gain Bandwidth (GBW).

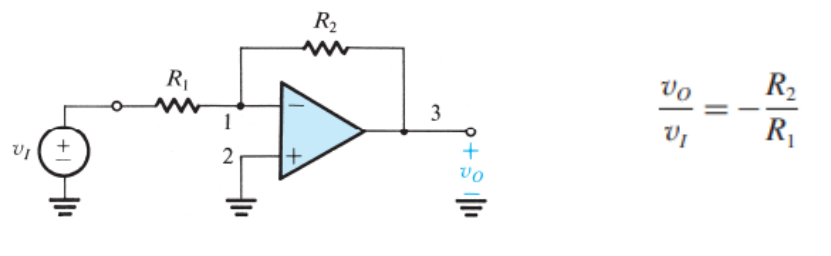

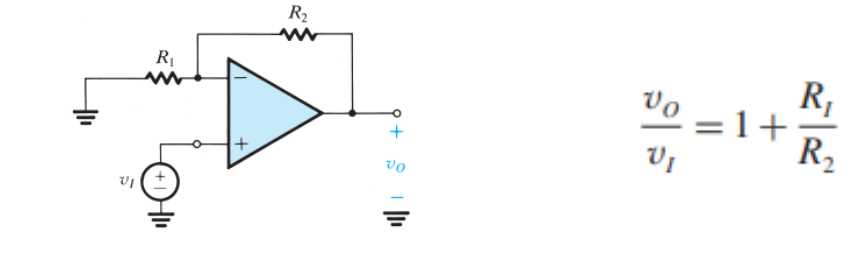

Using an infinite open-loop gain is limiting, as the output voltage signal would become saturated immediately. This could be useful in a comparator circuit. However, for most purposes some form of negative feedback is implemented to create a closed loop gain within the boundaries of the supply rails. Negative feedback amplifiers come in inverting (Figure 11) and non-inverting (Figure 12) configurations, with gain determined by the ratio of resistances seen by the negative feedback loop.

Inverting Op-Amp configuration and voltage gain equation 1.

Non-inverting Op-Amp configuration and voltage gain equation 1.

Non-idealities of real-life Op-Amps will also affect the circuit, the most influential of which is determined by a given IC’s strengths and weaknesses. A notable non-ideality can be seen in gain bandwidth and subsequent frequency response. Finite GBW/GBP of an Op-Amp produces attributes of an active lowpass filter. With the lower cutoff frequency determined by the GBP divided by the gain of the circuit 5. As a result, open-loop response often has high gain with very low cutoff frequency. Whereas closed-loop gain will keep gain approximately constant for a much wider bandwidth.

LM741 Frequency response in open and closed loop configurations 7.

Other non-idealities of Op-Amps are limits on output current, voltage, and slew rate. Output voltage can become saturated due to voltage gain exceeding the supply rails. Current supplied by an Op-Amp IC is highly dependent on a model, and current limits may be imposed for safety of the internal circuitry. The maximum rate of change for an Op-Amps output voltage is referred to as its slew rate. Op-Amps are slew rate limited at frequencies of operation that require a faster rate than the IC can permit.

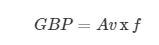

First-Order Filter Theory

Analog filters are a method of reducing gain of responses at certain frequencies. First-order filters implement a singular cutoff frequency while second order filters implement multiple cutoff frequencies. Filters can be implemented in active and passive configurations, meaning with and without Op-Amps respectively. Regardless of a filter being passive or active, Filter frequencies and modes of operation are created between RL and RC components. Figure 15 implements passive and active filters in multiple filter configurations.

First order filter table with active and passive applications 1.

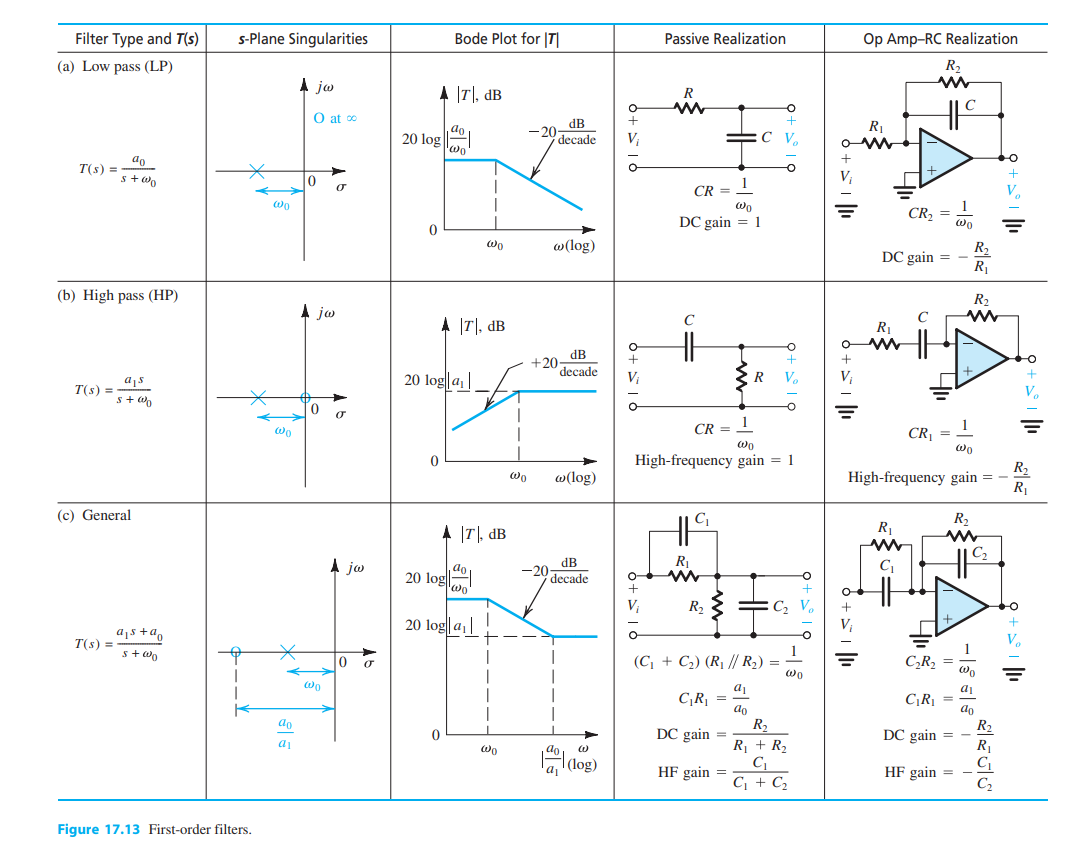

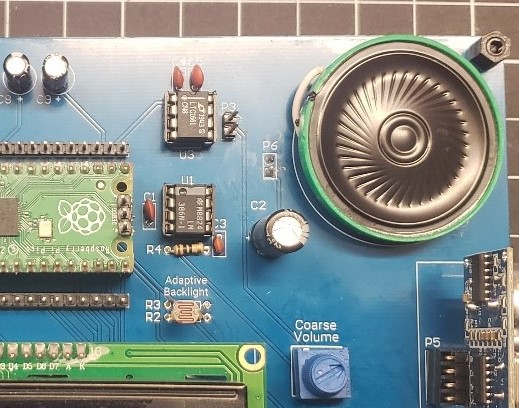

Audio Amplifier Configuration

The audio amplifier circuit has a simple implementation. The primary goal was creating a circuit with 26dB gain (20V/V) using the LM386. This was easily accomplished by referring to the LM386 datasheet as they provide applications in section 9 of the document (Figure 16) 9. Implementation can be seen on the schematic, Figure 22. I made no changes to the circuit recommended by the datasheet.

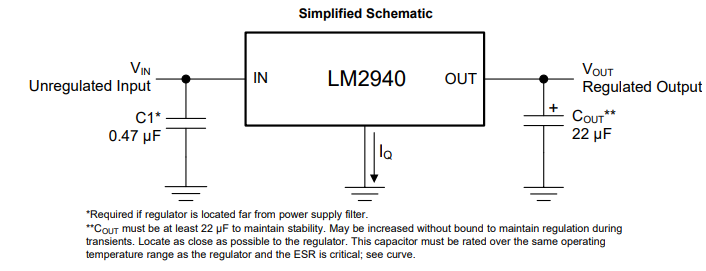

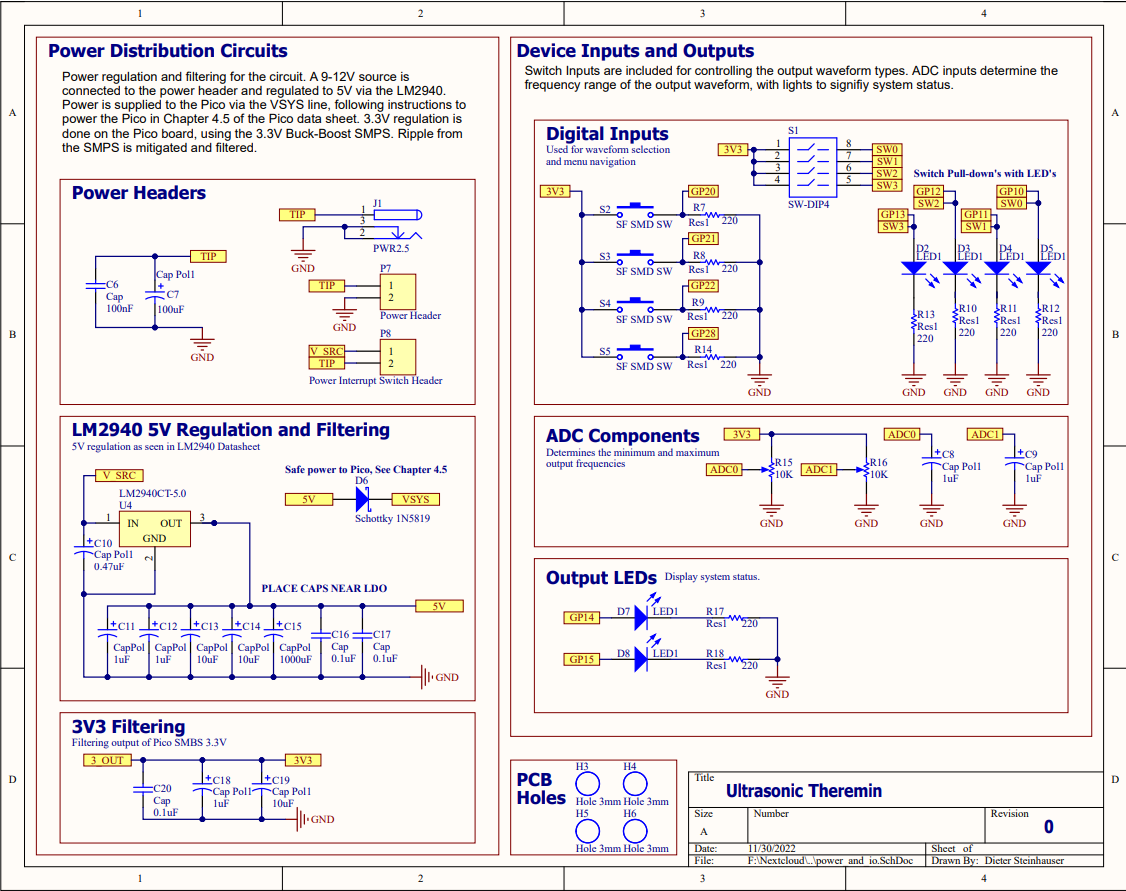

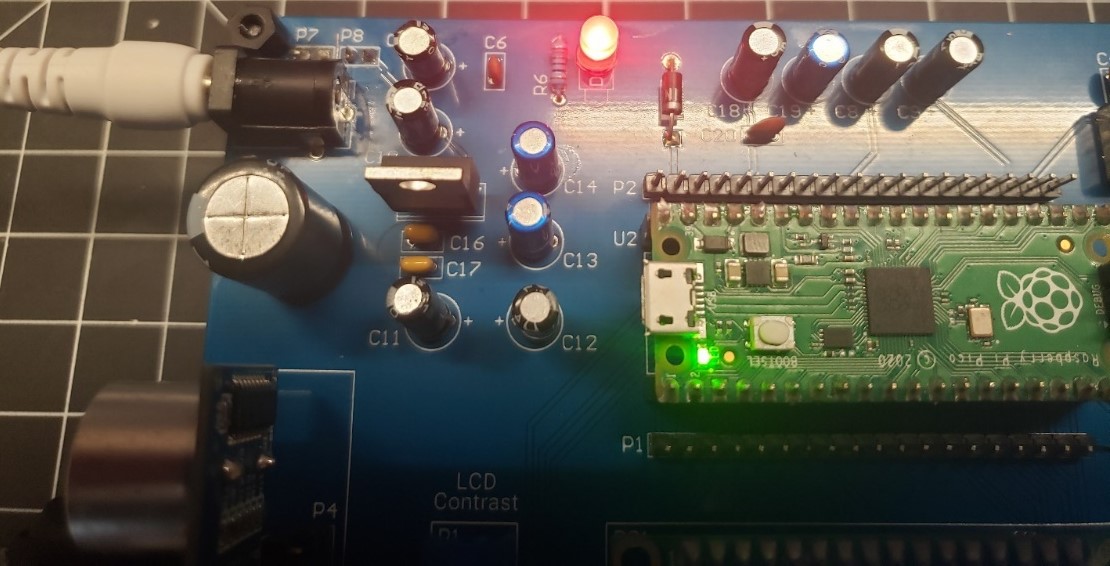

Power Regulation and Filtering

To supply power to the system, I chose to use the LM2940 5V low-dropout regulator. This allows for a 9-12V DC source to supply the devices without much overhead. This provided a smooth 5V source for most components, with local decoupling capacitors where needed. The LM2940 is a prime candidate for 5V regulation as its implementation is simple, only requiring two capacitors on the Vin and Vout 8. I implemented an array of values for the output capacitors out of an abundance of safety and a desire for a highly filtered power source 2, 18.

In addition to the 5V source, I powered the Raspberry Pico via the VSYS node to activate the device and use the 3.3V Switching Mode Power Supply (SMPS). This was done using a Schottky diode from 5V to VSYS to avoid backflow when the Pico is plugged in via USB 13. The Pico power-chain is good because the SMPS is efficient, but noise on the output causes problems with other systems like the ADC 13, 14. As a result, I added bypass capacitors to this source as well.

Pico Power-chain and the implemented method of external supply 8.

Inputs and Outputs

Buttons, switches, and LEDs are integrated into the design for various controls and system status. All inputs are setup in a pull-down configuration. Wave selection is controlled by the active switches while both menu selection and software resets are controlled by the buttons. This allows for a robust interface system to be implemented in software. GPIO selected for these pins were selected last to ensure critical systems had placement. Button debouncing was taken care of in software by implementing a delay after initial triggering. Alternatively, these buttons could be debounced using small bypass capacitors such as a 100nF, creating a linear voltage response for the IO pin instead of a bouncing signal. All buttons, switches, and output LED’s use the 3.3V source from the SMPS as to not damage GPIO pins on the Pico. They are also paired with 220-ohm resistors to give the LED’s maximum brightness in a safe current range.

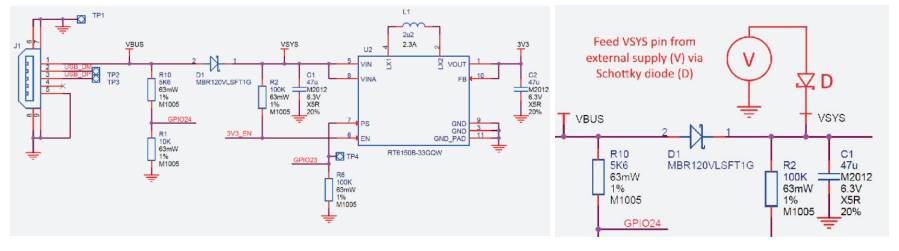

Ultrasonic Sensors

The HC-SR04 is an Ultrasonic sensor module that uses sonar to determine distance of objects similar to echolocation seen in animals like bats or dolphins 6. It is rated for distances of 2cm to 400cm and can provide high accuracy within this range. The sensors have four connections, VCC, Trig, Echo, and GND. The device operates with a 5V supply, while the trigger and echo are used to communicate digital data between the sensor and a microcontroller.

From the microcontroller, the Trig pin is set high for 10uS then brought low. This tells the sensor to send eight 40kHz bursts from the transmitter. The microcontroller should then poll the Echo pin, waiting for a high signal from the receiver, indicating the return of the bursts echo. The time between the rising and falling edge of the Echo pin can be used to calculate distance based on the speed of sound, 343 m/s. Based on the distances calculated from each sensor, we can modify output sound data.

LCD Configuration

Configuration of the Crystal Fontz AH1602Z-YYH for parallel communication was a major step in setup of this circuit. I chose to use parallel communication to interact with the LCD as opposed to SPI or I2C for simplicity and use of previous code. The LCD is wired in parallel to the microcontroller with four-bit communication 17. A potentiometer was connected for contrast control of the LCD, and a photoresistor and 1k-ohm resistor was connected in parallel for adaptive brightness control. For parallel communication, a nibble of data is sent to the display simultaneously. Full bytes of data are then sent to the device in a process called bit-banging. This splits a byte of data to send two nibbles in series, communicating the upper four bits and then the lower four bits. For wiring of the device, previous lecture slides and LCD driver manual were helpful in wiring and debugging issues with contrast and brightness 17.

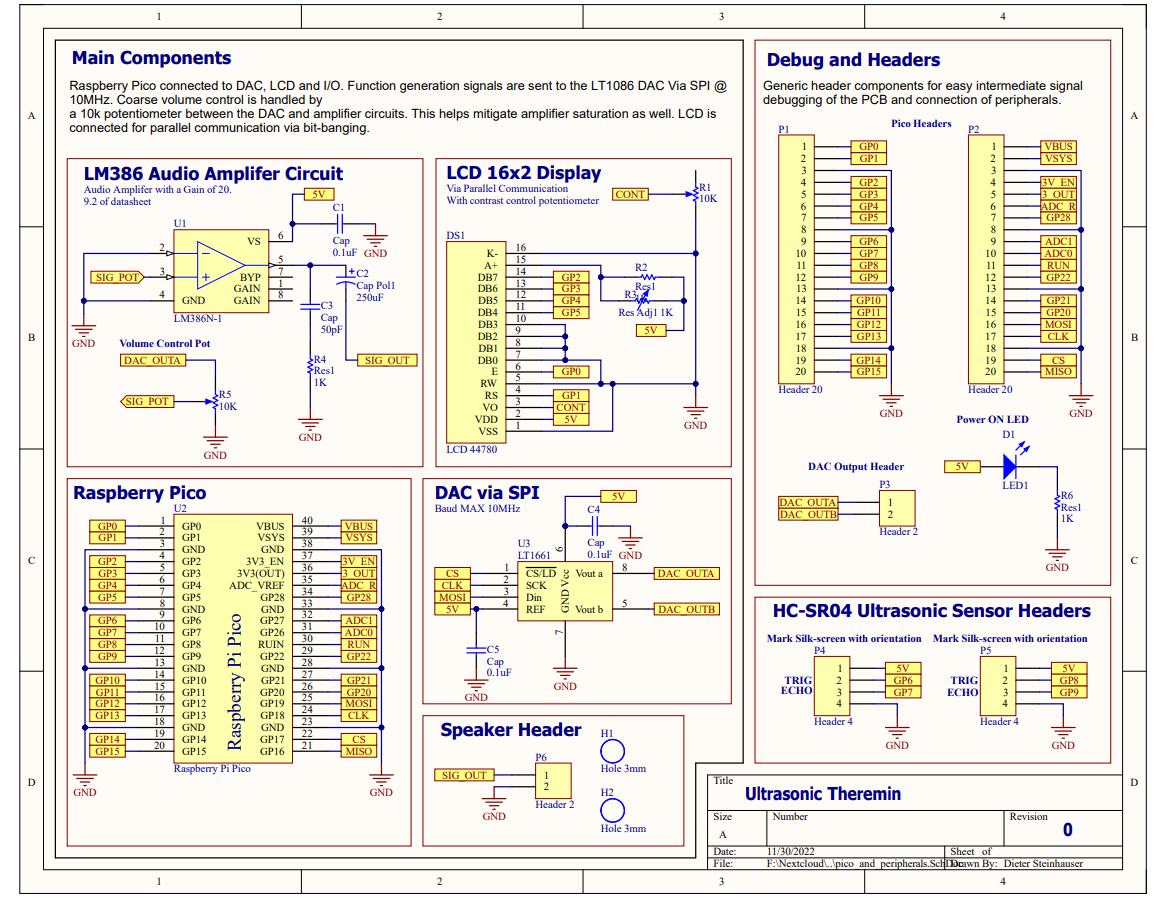

Theremin Circuit Configuration

The various components are connected in a circuit following the hardware diagram and schematics seen below. 9V Power is connected via a barrel jack and regulated to 5V, supplying the Pico through a Schottky diode. An LED is also driven by the 5V rail to indicate a power on status and a switch is present to cut off the 9V power to the circuit entirely. The 3.3V output of the Pico is used for all buttons, switches, and output LEDs. Two potentiometers are connected between 3.3V and ground with the wiper connecting to ADC pins, allowing variable analog input to the system. Switches, Buttons, and output LEDs are 3.3V pull-downs available for menu and waveform controls.

The DAC and audio amplifier are connected in series, followed by an 8-ohm speaker, presenting the Analog output waveform. Another potentiometer was connected between the DAC and amplifier to provide a coarse volume control on the output. Digital output in the form of Status LEDs indicate continuous operation by toggling and display on reset of the device.

Hardware Block Diagram of the Theremin Circuit.

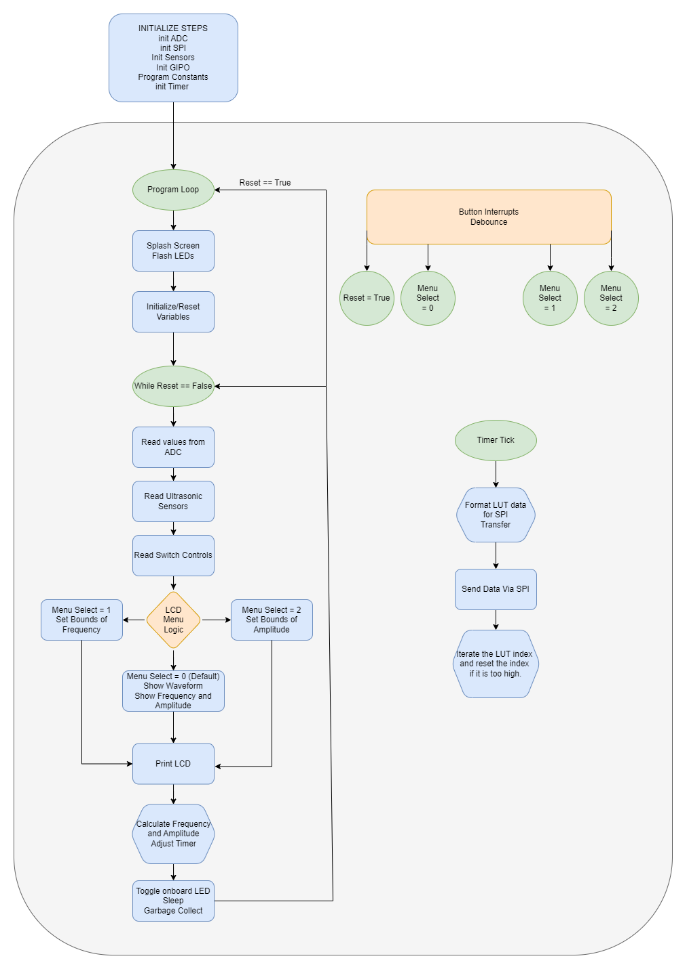

A single processor flow was employed for reliability and simplicity. To help speed up operations, a generous overclock was applied, setting the system clock to 270MHz. The Pico would start by initializing SPI communication at 10MHz, LCD parallel communication, and Ultrasonic sensor communication. This was followed by all other GPIO initialization, definition of button interrupts, and creating the waveform generation process in the timer tick.

The Pico would then enter its program loop, where a startup splash screen would be displayed along with lighting all LEDs. All variables would also be set to their default state. Pressing the reset button would return the user to this point in the program.

The main loop would then be entered and would continue until the reset button is pressed. In this process, the ADC, ultrasonic sensors, and switches are all polled for data. Depending on the state of the display menu set by button interrupts, the ADCs could set the frequency or amplitude range for computation later. The LCD prints a display associated with the current menu state. If both sensors detect the hands of the user, frequency and amplitude is then calculated based on the current boundaries for each and the ultrasonic sensor data. The timer is then started or adjusted for frequency shifts, and the processor sends SPI data to the DAC for output. If the sensors do not detect objects or a waveform is not selected with a switch, sound will not be output. Lastly, the onboard LED is toggled and the loop restarts for the duration of instrument use.

Software Block Diagram of the Theremin Circuit.

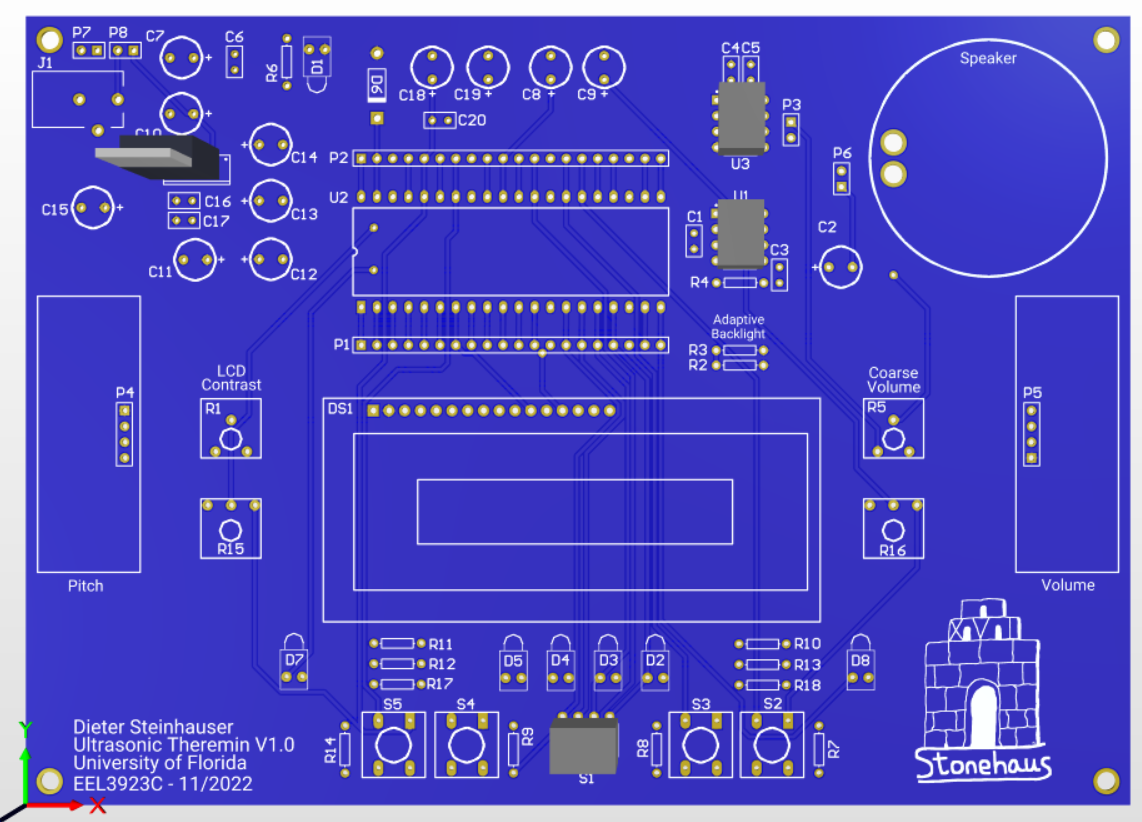

Schematic and PCB Design

All previously mentioned components must be compiled into a schematic design for wiring structure and PCB design. Useful tips and tricks for understanding the Altium can be learned by watching Professor Stapleton’s videos 11.

The most useful design points are regarding power and capacitor placement. Bypass and decoupling capacitors are added to the board for several reasons. First, capacitors can be used on power headers to avoid voltage spikes and removing AC ripple on DC power. Small ceramic caps offer low series resistance and react fast but have a difficult time dealing with substantial amounts of charge over long periods. Polarized electrolytic capacitors usually have a much higher capacitance, and in conjunction with smaller ceramic capacitors, effectively clean DC voltage 2, 11. In larger schematics and PCB’s, we are not always able to position circuits near bypass capacitors. Therefore, small decoupling capacitors are recommended for placement near a circuit subsection to help clean AC ripple from DC voltages 2.

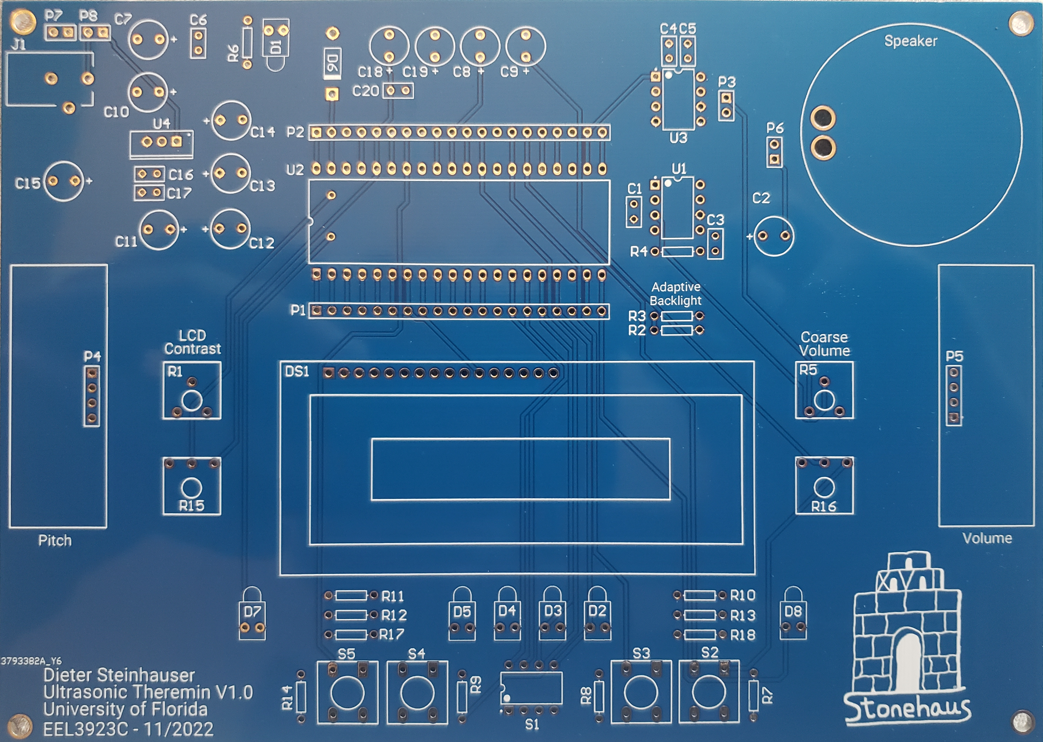

Once the schematic was populated with all necessary circuit components, the PCB was updated with all schematic components for board layout. A general layout of parts was done before resizing the board outline to find the most effective use of space. When all components have found their relative placement, routing traces for components using auto-routing tools or manually is required. I chose to auto-route, followed with manual edits to correct some trace routes. I found 20mil routes were sufficient for this circuit. Copper pours are also recommended for adding a ground or Vcc layer to the PCB, further simplifying routing design and common routes. I implemented a Ground and 5V layer using the copper pours.

Ultrasonic Theremin schematic page 1 of 2.

Ultrasonic Theremin schematic page 2 of 2.

Top side of Ultrasonic Theremin PCB layout.

Bill Of Materials

Name |

Description |

Designators |

Quantity |

Price |

Component Total |

1000uF Cap |

Electrolytic Capacitor |

C15 |

1 |

$1.60 |

$1.60 |

270uF Cap |

Electrolytic Capacitor |

C2 |

1 |

$0.33 |

$0.33 |

100uF Cap |

Electrolytic Capacitor |

C7 |

1 |

$0.09 |

$0.09 |

10uF Cap |

Electrolytic Capacitor |

C13, C14, C19 |

3 |

$0.07 |

$0.21 |

1uF Cap |

Electrolytic Capacitor |

C8, C9, C11, C12, C18 |

5 |

$0.06 |

$0.30 |

0.47uF Cap |

Electrolytic Capacitor |

C10 |

1 |

$0.09 |

$0.09 |

0.1uF Cap |

Ceramic Capacitor |

C1, C4, C5, C6, C16, C17, C20 |

7 |

$0.09 |

$0.63 |

50pF Cap |

Ceramic Capacitor |

C2 |

1 |

$0.17 |

$0.17 |

10K Pots |

3-pin Potentiometer |

R1, R5, R15, R16 |

4 |

$1.13 |

$4.52 |

1K Res |

axial Resistor |

R2, R4, R6 |

3 |

$0.05 |

$0.15 |

220 Res |

axial Resistor |

R7, R8, R9, R10, R11, R12, R13, R14, R17, R18 |

10 |

$0.03 |

$0.28 |

Photoresistor |

Photoresistor |

R3 |

1 |

$1.18 |

$1.18 |

LEDs |

5mm LED |

D1, D2, D3, D4, D5, D7, D8 |

7 |

$0.09 |

$0.63 |

LCD44780 |

16x2 LCD Display |

DS1 |

1 |

$6.27 |

$6.27 |

LTC1661 |

10bit DAC |

U3 |

1 |

$6.21 |

$6.21 |

LM386 |

Audio Amplifier |

U1 |

1 |

$1.50 |

$1.50 |

8 Ohm Speaker |

8 Ohm Speaker |

P6 |

1 |

$4.68 |

$4.68 |

LM2940 |

5V LDO Regulator |

U4 |

1 |

$2.70 |

$2.70 |

1N5819 |

Schottky Diode |

D6 |

1 |

$0.28 |

$0.28 |

9V Adapter |

AC/DC Adapter |

N/A |

1 |

$7.99 |

$7.99 |

Barrel Jack |

Female Connector |

P7 |

1 |

$0.71 |

$0.71 |

SPST Switch |

SPST Switch |

P8 |

1 |

$2.15 |

$2.15 |

HC-SR04 |

Ultrasonic Sensors |

P4, P5 |

2 |

$3.75 |

$7.50 |

Pico |

Raspberry Pico uP |

U2 |

1 |

$4.00 |

$4.00 |

SW_DIP 4 |

DIP Switch package |

S1 |

1 |

$0.59 |

$0.59 |

Buttons |

Buttons |

S2, S3, S4, S5 |

4 |

$1.18 |

$4.72 |

Project Total: |

$59.48 |

Results

The schematic of the circuit and PCB turned out well, with minimal errors. The assembled PCB was easy to debug because of its plentiful headers employed in the diagram. Also, using female headers for the ultrasonic sensors, LCD, DIP packages, and potentiometers aided debug and ensured that any errors in design could be more easily fixed if the PCB was routed wrong. Thankfully, there were no design breaking errors in this circuit, and most components worked immediately after installation.

Empty Theremin Circuit PCB.

Populated Theremin Circuit PCB.

Power

The power regulation and filtering produced a 5V source with minimal noise, observed with as little as 10mV ripple on the source. Extra filtering on the 3.3V source also seemed fruitful but may benefit from a larger array of capacitances to further smooth the ~30-40mV ripple observed on the device pin. This is a slight improvement on the unfiltered 3.3V rail.

Power regulation system on the PCB

5V source observed on the oscilloscope.

3.3V source observed on the oscilloscope.

Audio

The audio system of this circuit had no issue driving the 8-ohm speaker for a variety of 32-step waveforms. The coarse volume potentiometer helped easily remove clipping from the amplifier stage. Frequencies of 160Hz were achievable with system stability. Frequencies up to 240 were achieved using this audio configuration, however this boost is audio transaction demand.

Without Speaker Load

Audio output system.

Sine wave output of the Audio Amplifier without speaker load.

Square wave output of the Audio Amplifier without speaker load.

Triangle wave output of the Audio Amplifier without speaker load.

Sawtooth wave output of the Audio Amplifier without speaker load.

With Speaker Load

The audio amplifier with an 8-ohm speaker creates an RC circuit, and adds capacitive loading and unloading. Slight hiccupping of the output waveform can also be observed due to issues with the python interpreter, as well as variation in frequency/amplitude from ultrasonic sensors when sampling.

Sine wave output of the Audio Amplifier with speaker load.

Square wave output of the Audio Amplifier with speaker load.

Triangle wave output of the Audio Amplifier with speaker load.

Sawtooth wave output of the Audio Amplifier with speaker load.

Interface and Display

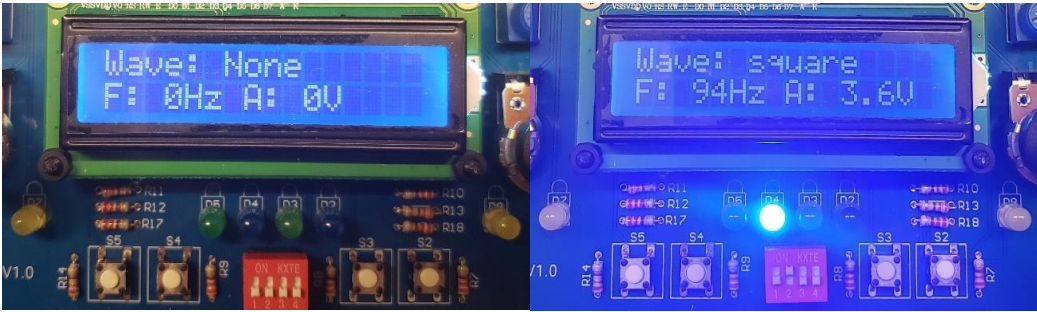

The finished theremin circuit displayed its menu system intuitively. On startup, the splash screen displays the project name and system clock, while holding the yellow and onboard LEDs high. After the splash screen, the system hits the home screen to display waveform, frequency, and amplitude readings in real time. DIP switches control the wave types, allowing sine, square, triangle, and sawtooth from left to right. Once both sensors detect objects, they display the potential frequency and amplitude of the wave. The output signal is only generated when both sensors detect, and a waveform switch is selected.

Splash screen on system reset.

Home screen with waveform selection, frequency, and amplitude readings.

Amplitude and frequency boundary menu.

Ultrasonic Theremin in its case.

Close up of the ultrasonic theremin in its case.

Discussion

Overall, the ultrasonic theremin circuit was a success. It has some minor problems that can be solved with small modifications to the PCB or software, but performs its task as expected. In terms of the power system, the regulation of the 5V source was excellent, however my smoothing of the 3.3V leaved something to be desired. This could be improved upon by adding more capacitance on the output rail. However, for our purposes of the 3.3V rail this is unnecessary. If I was to use the onboard ADC for more detail-oriented measurements, I would consider using an external LDO for 3.3V regulation, or work on filtering this 3.3V rail more. Regarding layout and the schematic, I believe that the design worked very well. There are minor changes for ease of use I would make with more time. These issues include moving C12 out of the Pico’s USB port area, taking more time to implement exact potentiometer footprints, and creating larger holes for the speaker wires.

The audio output system could be improved by adding a coupling capacitor on the signal line between the DAC and the LM386, as well as removal of the potentiometer from the signal path to reduce noise. With the removal of the potentiometer, it could alternatively be placed on the DAC reference to provide a similar result and reduce signal noise. LM386 amplification and filtering could be improved slightly, but for the purposes of this device I believe the current configuration is sufficient and could be improved mostly by my former critiques. Frequency range could also be improved by exploring multithreading, DMA, or other software efficiency systems to isolate data transactions to the DAC. Not exploring these avenues leaves considerable improvement available on the software architecture, but overclocking allowed for a proof of concept in demonstration.

Ultimately, the ultrasonic theremin was an interesting and unique project. We applied a variety of systems to bring together a working solution. Hardware included concepts of power regulation and filtering, I/O, LCD data display, and analog amplification. Software concepts of ADC and DAC conversions, interrupt service routines, debouncing, hardware timers, overclocking, parallel and SPI communication, and lookup tables were Implemented. Most systems were implemented well enough to meet project requirements and expectations. Room for improvement leaves potential for a revision of both the circuit and code, allowing for easier use, higher frequencies, and better responsiveness.

Appendix

LCD.py

1# ----------------------------------------- 2# NOTES 3# ----------------------------------------- 4""" 5Dieter Steinhauser 65/2023 7Parallel LCD functions, Configured for 4-bit communication. 8""" 9 10# ----------------------------------------- 11# IMPORTS 12# ----------------------------------------- 13 14from machine import Pin 15import utime 16 17# ----------------------------------------- 18# CONSTANTS AND VARIABLES 19# ----------------------------------------- 20 21# CONSTANTS 22# ---------------------- 23 24LCD_CMD = 0 25LCD_DATA = 1 26 27# ---------------------- 28# GPIO Wiring: Legacy Structure 29# ---------------------- 30 31EN = Pin(0, Pin.OUT) # Enable Pin 32RS = Pin(1, Pin.OUT) # Register Select 33 34PINS = [5, 4, 3, 2] 35# Pin numbers for the upper nibble, does the below assignment in configure method. 36# D4 = Pin(2, Pin.OUT) 37# D5 = Pin(3, Pin.OUT) 38# D6 = Pin(4, Pin.OUT) 39# D7 = Pin(5, Pin.OUT) 40 41# list that gets populated with pinout objects for data line. 42DATA_BUS = [] 43 44# ----------------------------------------- 45# METHODS 46# ----------------------------------------- 47 48def Configure(): 49 """Creates the data bus object from the pin list""" 50 51 for index in range(4): 52 DATA_BUS.append(Pin(PINS[index], Pin.OUT)) 53 54# ----------------------------------------- 55 56def lcd_strobe(): 57 """Flashes the enable line and provides wait period.""" 58 59 EN.value(1) 60 utime.sleep_ms(1) 61 62 EN.value(0) 63 utime.sleep_ms(1) 64 65# ----------------------------------------- 66 67def lcd_write(command, mode): 68 """Sends data to the LCD module. """ 69 70 # determine if writing a command or data 71 data = command if mode == 0 else ord(command) 72 73 # need upper nibble for first loop. lower nibble can use data directly. 74 upper = data >> 4 75 76 # write the upper nibble 77 for index in range(4): 78 bit = upper & 1 79 DATA_BUS[index].value(bit) 80 upper = upper >> 1 81 82 # strobe the LCD, sending the nibble 83 RS.value(mode) 84 lcd_strobe() 85 86 # write the lower nibble 87 for index in range(4): 88 bit = data & 1 89 DATA_BUS[index].value(bit) 90 data = data >> 1 91 92 # Strobe the LCD, sending the nibble 93 RS.value(mode) 94 lcd_strobe() 95 utime.sleep_ms(1) 96 RS.value(1) 97 98# ----------------------------------------- 99 100def lcd_clear(): 101 """Clear the LCD Screen.""" 102 103 lcd_write(0x01, 0) 104 utime.sleep_ms(5) 105 106# ----------------------------------------- 107 108def lcd_home(): 109 """Return the Cursor to the starting position.""" 110 111 lcd_write(0x02, 0) 112 utime.sleep_ms(5) 113 114# ----------------------------------------- 115 116 117def lcd_cursor_blink(): 118 """Have the cursor start blinking.""" 119 120 lcd_write(0x0D, 0) 121 utime.sleep_ms(1) 122 123# ----------------------------------------- 124 125def lcd_cursor_on(): 126 """Have the cursor on, Good for debugging.""" 127 128 lcd_write(0x0E, 0) 129 utime.sleep_ms(1) 130 131# ----------------------------------------- 132 133def lcd_cursor_off(): 134 """Turn the cursor off.""" 135 136 lcd_write(0x0C, 0) 137 utime.sleep_ms(1) 138 139# ----------------------------------------- 140 141def lcd_puts(string): 142 """Write a string on to the LCD.""" 143 144 for element in string: 145 lcd_putch(element) 146 147# ----------------------------------------- 148 149def lcd_putch(c): 150 """Write a character on to the LCD.""" 151 lcd_write(c, 1) 152 153# ----------------------------------------- 154 155def lcd_goto(column, row): 156 157 158 if row == 0: 159 address = 0 160 161 if row == 1: 162 address = 0x40 163 164 if row == 2: 165 address = 0x14 166 167 if row == 3: 168 address = 0x54 169 170 address = address + column 171 lcd_write(0x80 | address, 0) 172 173# ----------------------------------------- 174 175def lcd_init(): 176 177 # Configure the pins of the device. 178 Configure() 179 utime.sleep_ms(120) 180 181 # clear values on data bus. 182 for index in range(4): 183 DATA_BUS[index].value(0) 184 utime.sleep_ms(50) 185 186 # initialization sequence. 187 DATA_BUS[0].value(1) 188 DATA_BUS[1].value(1) 189 lcd_strobe() 190 utime.sleep_ms(10) 191 192 lcd_strobe() 193 utime.sleep_ms(10) 194 195 lcd_strobe() 196 utime.sleep_ms(10) 197 198 DATA_BUS[0].value(0) 199 lcd_strobe() 200 utime.sleep_ms(5) 201 202 lcd_write(0x28, 0) 203 utime.sleep_ms(1) 204 205 lcd_write(0x08, 0) 206 utime.sleep_ms(1) 207 208 lcd_write(0x01, 0) 209 utime.sleep_ms(10) 210 211 lcd_write(0x06, 0) 212 utime.sleep_ms(5) 213 214 lcd_write(0x0C, 0) 215 utime.sleep_ms(10) 216 217 218# ----------------------------------------- 219# LCD Class: 220# ----------------------------------------- 221 222 223class LCD: 224 """The LCD class is meant to abstract the LCD driver further and streamline development.""" 225 226 CMD_MODE = 0 227 DATA_MODE = 1 228 229 def __init__(self, enable_pin: int, reg_select_pin: int, data_pins: list) -> None: 230 """Object initialization""" 231 232 self.enable_pin = Pin(enable_pin, Pin.OUT) 233 self.reg_select_pin = Pin(reg_select_pin, Pin.OUT) 234 self._data_pins = data_pins 235 self.data_bus = [] 236 237 # Configure the pins of the device. 238 self._configure() 239 utime.sleep_ms(120) 240 241 # ----------------------------------------- 242 243 def _configure(self): 244 """Creates the data bus object from the pin list. """ 245 246 # Configure the pins of the device. 247 for element in self._data_pins: 248 self.data_bus.append(Pin(element, Pin.OUT)) 249 250 # ----------------------------------------- 251 252 def init(self): 253 """Initializes the LCD for communication.""" 254 255 # clear values on data bus. 256 for index in range(4): 257 self.data_bus[index].value(0) 258 utime.sleep_ms(50) 259 260 # initialization sequence. 261 self.data_bus[0].value(1) 262 self.data_bus[1].value(1) 263 self.strobe() 264 utime.sleep_ms(10) 265 266 self.strobe() 267 utime.sleep_ms(10) 268 269 self.strobe() 270 utime.sleep_ms(10) 271 272 self.data_bus[0].value(0) 273 self.strobe() 274 utime.sleep_ms(5) 275 276 self.write(0x28, 0) 277 utime.sleep_ms(1) 278 279 self.write(0x08, 0) 280 utime.sleep_ms(1) 281 282 self.write(0x01, 0) 283 utime.sleep_ms(10) 284 285 self.write(0x06, 0) 286 utime.sleep_ms(5) 287 288 self.write(0x0C, 0) 289 utime.sleep_ms(10) 290 291 # ----------------------------------------- 292 293 def strobe(self): 294 """Flashes the enable line and provides wait period.""" 295 296 self.enable_pin.value(1) 297 utime.sleep_ms(1) 298 299 self.enable_pin.value(0) 300 utime.sleep_ms(1) 301 302 # ----------------------------------------- 303 304 def write(self, command, mode): 305 """Sends data to the LCD module. """ 306 307 # determine if writing a command or data 308 data = command if mode == 0 else ord(command) 309 310 # need upper nibble for first loop. lower nibble can use data directly. 311 upper = data >> 4 312 313 # write the upper nibble 314 for index in range(4): 315 bit = upper & 1 316 self.data_bus[index].value(bit) 317 upper = upper >> 1 318 319 # strobe the LCD, sending the nibble 320 self.reg_select_pin.value(mode) 321 self.strobe() 322 323 # write the lower nibble 324 for index in range(4): 325 bit = data & 1 326 self.data_bus[index].value(bit) 327 data = data >> 1 328 329 # Strobe the LCD, sending the nibble 330 self.reg_select_pin.value(mode) 331 self.strobe() 332 utime.sleep_ms(1) 333 self.reg_select_pin.value(1) 334 335 # ----------------------------------------- 336 337 def clear(self): 338 """Clear the LCD Screen.""" 339 340 self.write(0x01, 0) 341 utime.sleep_ms(5) 342 343 # ----------------------------------------- 344 345 def home(self): 346 """Return the Cursor to the starting position.""" 347 348 self.write(0x02, 0) 349 utime.sleep_ms(5) 350 351 # ----------------------------------------- 352 353 354 def blink(self): 355 """Have the cursor start blinking.""" 356 357 self.write(0x0D, 0) 358 utime.sleep_ms(1) 359 360 # ----------------------------------------- 361 362 def cursor_on(self): 363 """Have the cursor on, Good for debugging.""" 364 365 self.write(0x0E, 0) 366 utime.sleep_ms(1) 367 368 # ----------------------------------------- 369 370 def cursor_off(self): 371 """Turn the cursor off.""" 372 373 self.write(0x0C, 0) 374 utime.sleep_ms(1) 375 376 # ----------------------------------------- 377 378 def print(self, string): 379 """Write a string on to the LCD.""" 380 381 for element in string: 382 self._putch(element) 383 384 # ----------------------------------------- 385 386 def _putch(self, c): 387 """Write a character on to the LCD.""" 388 self.write(c, 1) 389 390 # ----------------------------------------- 391 392 def _puts(self, string): 393 """Write a string on to the LCD.""" 394 395 for element in string: 396 self._putch(element) 397 398 399 # ----------------------------------------- 400 def go_to(self, column, row): 401 402 403 if row == 0: 404 address = 0 405 406 if row == 1: 407 address = 0x40 408 409 if row == 2: 410 address = 0x14 411 412 if row == 3: 413 address = 0x54 414 415 address = address + column 416 self.write(0x80 | address, 0) 417 418 419# ----------------------------------------- 420# END OF FILE 421# -----------------------------------------

LUT.py

1# ----------------------------------------- 2# NOTES 3# ----------------------------------------- 4""" 5 6Dieter Steinhauser 710/1/2022 8Design 1 9DAC Lookup Tables 10 11The following are lists of 32 and 256 words that assemble one period 12of a waveform 13""" 14 15# ----------------------------------------- 16# CONSTANTS 17# ----------------------------------------- 18 19FREQ_MAX = 100 20FREQ_MIN = 10 21DAC_WRITE_THRU_A = 0x9 << 12 # WRITE_THRU_A 22DAC_WRITE_THRU_B = 0xA << 12 # WRITE_THRU_B 23 24# ----------------------------------------- 25# LUTS 26# ----------------------------------------- 27 28# 10 bit res 29SQUARE_WAVE_LUT = [0]*16 + [1023]*16 30 31SQUARE_WAVE_LUT_256 = [0]*128 + [1023]*128 32 33 34# 10 bit res 35SAWTOOTH_WAVE_LUT = list(range(0, 1023, 32)) 36 37SAWTOOTH_WAVE_LUT_256 = list(range(0, 1023, 4)) 38 39 40# 10 bit res 41SINE_WAVE_LUT = [0x200,0x264,0x2c4,0x31c,0x36a,0x3aa,0x3d9,0x3f6,0x400,0x3f6,0x3d9,0x3aa,0x36a,0x31c,0x2c4,0x264, 420x200,0x19c,0x13c,0xe4,0x96,0x56,0x27,0xa,0x0,0xa,0x27,0x56,0x96,0xe4,0x13c,0x19c] 43 44 45SINE_WAVE_LUT_256 = [0x200,0x20c,0x219,0x225,0x232,0x23e,0x24b,0x257,0x263,0x270,0x27c,0x288,0x294,0x2a0,0x2ac,0x2b8, 460x2c3,0x2cf,0x2da,0x2e5,0x2f1,0x2fc,0x306,0x311,0x31c,0x326,0x330,0x33a,0x344,0x34e,0x357,0x360, 470x369,0x372,0x37a,0x383,0x38b,0x393,0x39a,0x3a2,0x3a9,0x3b0,0x3b6,0x3bd,0x3c3,0x3c8,0x3ce,0x3d3, 480x3d8,0x3dd,0x3e1,0x3e5,0x3e9,0x3ec,0x3f0,0x3f3,0x3f5,0x3f7,0x3f9,0x3fb,0x3fd,0x3fe,0x3fe,0x3ff, 490x3ff,0x3ff,0x3fe,0x3fe,0x3fd,0x3fb,0x3f9,0x3f7,0x3f5,0x3f3,0x3f0,0x3ec,0x3e9,0x3e5,0x3e1,0x3dd, 500x3d8,0x3d3,0x3ce,0x3c8,0x3c3,0x3bd,0x3b6,0x3b0,0x3a9,0x3a2,0x39a,0x393,0x38b,0x383,0x37a,0x372, 510x369,0x360,0x357,0x34e,0x344,0x33a,0x330,0x326,0x31c,0x311,0x306,0x2fc,0x2f1,0x2e5,0x2da,0x2cf, 520x2c3,0x2b8,0x2ac,0x2a0,0x294,0x288,0x27c,0x270,0x263,0x257,0x24b,0x23e,0x232,0x225,0x219,0x20c, 530x200,0x1f3,0x1e6,0x1da,0x1cd,0x1c1,0x1b4,0x1a8,0x19c,0x18f,0x183,0x177,0x16b,0x15f,0x153,0x147, 540x13c,0x130,0x125,0x11a,0x10e,0x103,0xf9,0xee,0xe3,0xd9,0xcf,0xc5,0xbb,0xb1,0xa8,0x9f, 550x96,0x8d,0x85,0x7c,0x74,0x6c,0x65,0x5d,0x56,0x4f,0x49,0x42,0x3c,0x37,0x31,0x2c, 560x27,0x22,0x1e,0x1a,0x16,0x13,0xf,0xc,0xa,0x8,0x6,0x4,0x2,0x1,0x1,0x0, 570x0,0x0,0x1,0x1,0x2,0x4,0x6,0x8,0xa,0xc,0xf,0x13,0x16,0x1a,0x1e,0x22, 580x27,0x2c,0x31,0x37,0x3c,0x42,0x49,0x4f,0x56,0x5d,0x65,0x6c,0x74,0x7c,0x85,0x8d, 590x96,0x9f,0xa8,0xb1,0xbb,0xc5,0xcf,0xd9,0xe3,0xee,0xf9,0x103,0x10e,0x11a,0x125,0x130, 600x13c,0x147,0x153,0x15f,0x16b,0x177,0x183,0x18f,0x19c,0x1a8,0x1b4,0x1c1,0x1cd,0x1da,0x1e6,0x1f3] 61 62# 10 bit res 63TRIANGLE_WAVE_LUT = [0x40,0x80,0xc0,0x100,0x140,0x180,0x1c0,0x200,0x240,0x280,0x2c0,0x300,0x340,0x380,0x3c0,0x400, 640x3c0,0x380,0x340,0x300,0x2c0,0x280,0x240,0x200,0x1c0,0x180,0x140,0x100,0xc0,0x80,0x40,0x0] 65 66TRIANGLE_WAVE_LUT_256 = [0x8,0x10,0x18,0x20,0x28,0x30,0x38,0x40,0x48,0x50,0x58,0x60,0x68,0x70,0x78,0x80, 670x88,0x90,0x98,0xa0,0xa8,0xb0,0xb8,0xc0,0xc8,0xd0,0xd8,0xe0,0xe8,0xf0,0xf8,0x100, 680x108,0x110,0x118,0x120,0x128,0x130,0x138,0x140,0x148,0x150,0x158,0x160,0x168,0x170,0x178,0x180, 690x188,0x190,0x198,0x1a0,0x1a8,0x1b0,0x1b8,0x1c0,0x1c8,0x1d0,0x1d8,0x1e0,0x1e8,0x1f0,0x1f8,0x200, 700x207,0x20f,0x217,0x21f,0x227,0x22f,0x237,0x23f,0x247,0x24f,0x257,0x25f,0x267,0x26f,0x277,0x27f, 710x287,0x28f,0x297,0x29f,0x2a7,0x2af,0x2b7,0x2bf,0x2c7,0x2cf,0x2d7,0x2df,0x2e7,0x2ef,0x2f7,0x2ff, 720x307,0x30f,0x317,0x31f,0x327,0x32f,0x337,0x33f,0x347,0x34f,0x357,0x35f,0x367,0x36f,0x377,0x37f, 730x387,0x38f,0x397,0x39f,0x3a7,0x3af,0x3b7,0x3bf,0x3c7,0x3cf,0x3d7,0x3df,0x3e7,0x3ef,0x3f7,0x3ff, 740x3f7,0x3ef,0x3e7,0x3df,0x3d7,0x3cf,0x3c7,0x3bf,0x3b7,0x3af,0x3a7,0x39f,0x397,0x38f,0x387,0x37f, 750x377,0x36f,0x367,0x35f,0x357,0x34f,0x347,0x33f,0x337,0x32f,0x327,0x31f,0x317,0x30f,0x307,0x2ff, 760x2f7,0x2ef,0x2e7,0x2df,0x2d7,0x2cf,0x2c7,0x2bf,0x2b7,0x2af,0x2a7,0x29f,0x297,0x28f,0x287,0x27f, 770x277,0x26f,0x267,0x25f,0x257,0x24f,0x247,0x23f,0x237,0x22f,0x227,0x21f,0x217,0x20f,0x207,0x200, 780x1f8,0x1f0,0x1e8,0x1e0,0x1d8,0x1d0,0x1c8,0x1c0,0x1b8,0x1b0,0x1a8,0x1a0,0x198,0x190,0x188,0x180, 790x178,0x170,0x168,0x160,0x158,0x150,0x148,0x140,0x138,0x130,0x128,0x120,0x118,0x110,0x108,0x100, 800xf8,0xf0,0xe8,0xe0,0xd8,0xd0,0xc8,0xc0,0xb8,0xb0,0xa8,0xa0,0x98,0x90,0x88,0x80, 810x78,0x70,0x68,0x60,0x58,0x50,0x48,0x40,0x38,0x30,0x28,0x20,0x18,0x10,0x8,0x0] 82 83 84# ----------------------------------------- 85# STRUCTURES 86# ----------------------------------------- 87 88 89class Waveform: 90 """Class to store info on the waveform functions""" 91 92 def __init__(self, switch: str, name: str, lut: list): 93 94 size = len(lut) 95 self.switch = switch #: Switch associated with the waveform 96 self.name = name #: Name String of the waveform 97 self.lut = lut #: Lookup table for the waveform 98 self.size = size #: size of the lookup table 99 self.last_index = size - 1 #: last index of the lookup table 100 101 # Generate the burst table. This formats data for continuous writing of words to the DAC. 102 burst_lut = [] 103 for element in lut: 104 burst_lut.append(DAC_WRITE_THRU_A | (element << 2)) 105 106 self.burst_lut = burst_lut #: Word table for continuous writing of data to the DAC through DMA. 107 108 109sine = Waveform('SW0', 'sine ', SINE_WAVE_LUT) 110square = Waveform('SW1', 'square ', SQUARE_WAVE_LUT) 111triangle = Waveform('SW2', 'triangle', TRIANGLE_WAVE_LUT) 112sawtooth = Waveform('SW3', 'sawtooth', SAWTOOTH_WAVE_LUT) 113 114waveforms = {'SW0': sine, 115 'SW1': square, 116 'SW2': triangle, 117 'SW3': sawtooth} 118 119 120# ----------------------------------------- 121# END OF FILE 122# ----------------------------------------- 123 124 125

spi_config.py

1# ----------------------------------------- 2# NOTES 3# ----------------------------------------- 4""" 5 6Dieter Steinhauser 711/2022 8Design 1 9SPI configuration 10 11The following is configuration of SPI communication for the LTC1661 10-bit DAC. 12""" 13 14# ----------------------------------------- 15# IMPORTS 16# ----------------------------------------- 17from machine import Pin, SPI 18 19# ----------------------------------------- 20# CONSTANTS 21# ----------------------------------------- 22DEBUG_SPI_CLK = 1_000_000 # Hz 23STABLE_SPI_CLK = 8_000_000 # Hz 24FAST_SPI_CLK = 10_000_000 # Hz 25IDLE_LO = 0 26IDLE_HI = 1 27RISING_EDGE = 0 28FALLING_EDGE = 1 29 30# ----------------------------------------- 31# SPI 32# ----------------------------------------- 33 34# Note: How to configure SPI 35# --------------------------- 36# spi.init(baudrate=1_000_000, # clock speed 37 # polarity=0, # Idle clock level. 0:L, 1:H 38 # phase=0, # sample on rising(0) or falling (1) edge 39 # bits=8, # width of transfer in bits, 8 is standard 40 # firstbit=SPI.MSB, # bit order, either SPI.MSB or SPI.LSB 41 # sck=None, # alternate pin object selection 42 # mosi=None, # alternate pin object selection 43 # miso=None, # alternate pin object selection 44 # pins=(SCK, MOSI, MISO) # alternate pin object selection for WiPy 45 # ) 46 47# spi.write('test') # single write to the device 48# spi.read(num_bytes) # read a number of bytes. can take a second parameter of a continuous write byte value. 49# 50# buf = bytearray(3) 51# spi.write_readinto('out', read_buf) # writes the first value while reading into the second parameter read_buf 52# --------------------------- 53 54spi_clock_speed = FAST_SPI_CLK 55spi = SPI(0) 56# Default Pins for SPI-0 57# CLK - 18 58# MOSI - 19 59# MISO - 16 60# CS - 17 #Note, if this does not work immeadiately, enable the pin as an output as seen below. 61 62cs = Pin(17, Pin.OUT, value=1) 63 64spi.init(baudrate=spi_clock_speed, # clock speed 65 polarity=IDLE_LO, # Idle clock level. 0:L, 1:H 66 phase=RISING_EDGE, # sample on rising(0) or falling (1) edge 67 )

theremin.py

1# ----------------------------------------- 2# NOTES 3# ----------------------------------------- 4""" 5Dieter Steinhauser 611/2022 7Design 1 8Ultrasonic Theremin 9 10This program employs talks to various peripherals to create a theremin music device. 11 12The Major components include: 13Transfers of SPI data to DAC 14LCD status 15ADC conversions 16Switch inputs 17button inputs 18Overclocking 19 20Potentially: 21multithreading 22DMA 23 24""" 25 26# ----------------------------------------- 27# IMPORTS 28# ----------------------------------------- 29 30from LCD import * 31from LUT import * 32from spi_config import * 33import _thread 34from utime import sleep, sleep_ms, sleep_us, ticks_ms 35from machine import Pin, Timer, ADC, freq 36 37# ----------------------------------------- 38# CONSTANTS/VARIABLES 39# ----------------------------------------- 40 41# ------------------ 42REFRESH_RATE = 60 # Frequency in Hz 43REFRESH_PERIOD = int((1 / REFRESH_RATE) * 1000) # delay in milliseconds 44 45# ------------------ 46UPY_BIT_RES = 16 47ADC_REF = 3.3 48VOLT_PER_BIT = ADC_REF / (2**UPY_BIT_RES) # ADC recieves in 2 byte packets and micropython automagically fixes it. 49 50# ------------------ 51DAC_REF = 5.0 52DC_OFFSET = 0 53DC_OFFSET_RES = int((DC_OFFSET / DAC_REF) * (2**UPY_BIT_RES)) 54 55# ------------------ 56FREQ_MAX = 100 57FREQ_MIN = 10 58AMP_MAX = DAC_REF 59AMP_MIN = 0 60 61MAX_DIST_US0 = 50 62MAX_DIST_US1 = 20 63 64# ----------------------------------------- 65# METHODS 66# ----------------------------------------- 67 68def append_space(string, length): 69 while (len(string) < length): 70 string = ' ' + string 71 return string 72 73# ------------------------------------------------------------- 74# INITIALIZATION 75# ------------------------------------------------------------- 76 77# ----------------------------------------- 78# SYSTEM CLOCK 79# ----------------------------------------- 80 81DEFAULT_SYS_CLK = 125_000_000 82STABLE_OVERCLOCK = 270_000_000 83 84# Pico can go up to 270MHz before needing to flash to the eeprom directly. 85system_clock = STABLE_OVERCLOCK 86 87# if the system clock is not the default, apply the clock speed. 88if system_clock != DEFAULT_SYS_CLK: 89 freq(system_clock) 90 91# print(f'Clock: {freq()/1e6}MHz') 92 93# ----------------------------------------- 94# PINOUT 95# ----------------------------------------- 96 97# LCD Pins handled in LCD.py 98# ---------------------------- 99# EN = Pin(0, Pin.OUT) 100# RS = Pin(1, Pin.OUT) 101# D7 = Pin(2, Pin.OUT) 102# D6 = Pin(3, Pin.OUT) 103# D5 = Pin(4, Pin.OUT) 104# D4 = Pin(5, Pin.OUT) 105 106# Ultrasonic sensor pins handled in sensors.py 107# ---------------------------- 108# us0_trig = Pin(6, Pin.OUT) 109# us0_echo = Pin(7, Pin.IN) 110# us1_trig = Pin(8, Pin.OUT) 111# us1_echo = Pin(9, Pin.IN) 112 113# Switches 114# ---------------------------- 115sw0 = Pin(10, Pin.IN, Pin.PULL_DOWN) 116sw1 = Pin(11, Pin.IN, Pin.PULL_DOWN) 117sw2 = Pin(12, Pin.IN, Pin.PULL_DOWN) 118sw3 = Pin(13, Pin.IN, Pin.PULL_DOWN) 119switch_pins = [sw0, sw1, sw2, sw3] 120 121# LEDs 122# ---------------------------- 123led0 = Pin(14, Pin.OUT) 124led1 = Pin(15, Pin.OUT) 125led_onboard = Pin(25, Pin.OUT) 126led_pins = [led0, led1, led_onboard] 127 128# SPI handled by the Hardware in spi_config.py 129# ---------------------------- 130# miso = Pin(16, Pin.IN) 131# cs = Pin(17, Pin.OUT, value=1) 132# mosi = Pin(18, Pin.OUT) 133# sck = Pin(19, Pin.OUT) 134 135# Buttons 136# ---------------------------- 137button0 = Pin(20, Pin.IN) 138button1 = Pin(21, Pin.IN) 139button2 = Pin(22, Pin.IN) 140button3 = Pin(28, Pin.IN) 141button_pins = [button0, button1, button2, button3] 142 143# ADC 144# ---------------------------- 145# adc0 = ADC(26) # Connect to GP26, which is channel 0 146# adc1 = ADC(27) # Connect to GP27, which is channel 1 147 148 149# ----------------------------------------- 150# GENERAL I/O 151# ----------------------------------------- 152last_time = 0 153def debounce(): 154 global last_time 155 new_time = ticks_ms() 156 # if it has been more that 1/10 of a second since the last event, we have a new event 157 if (new_time - last_time) > 100: 158 last_time = new_time 159 return True 160 else: 161 return False 162 163def button0_irq_handler(pin): 164 global reset 165 if (debounce()): 166 reset = True 167 168def button1_irq_handler(pin): 169 global menu_select 170 if (debounce()): 171 menu_select = 0 172 173def button2_irq_handler(pin): 174 global menu_select 175 if (debounce()): 176 menu_select = 1 177 178def button3_irq_handler(pin): 179 global menu_select 180 if (debounce()): 181 menu_select = 2 182 183# now we register the handler function when the button is pressed 184button0.irq(trigger=Pin.IRQ_RISING, handler = button0_irq_handler) 185button1.irq(trigger=Pin.IRQ_RISING, handler = button1_irq_handler) 186button2.irq(trigger=Pin.IRQ_RISING, handler = button2_irq_handler) 187button3.irq(trigger=Pin.IRQ_RISING, handler = button3_irq_handler) 188 189 190# ----------------------------------------- 191# ULTRASONIC SENSORS 192# ----------------------------------------- 193 194 195from machine import Pin 196from utime import ticks_us, sleep_us 197 198# Ultrasonic sensor pins 199# ---------------------------- 200us0_trig = Pin(6, Pin.OUT) 201us0_echo = Pin(7, Pin.IN) 202us1_trig = Pin(8, Pin.OUT) 203us1_echo = Pin(9, Pin.IN) 204 205def get_distance_u0(): 206 207 # send the trigger wave 208 us0_trig(1) 209 sleep_us(1) 210 us0_trig(0) 211 212 # listen for the return echo 213 while us0_echo.value() == 0: 214 start = ticks_us() 215 while us0_echo.value() == 1: 216 stop = ticks_us() 217 218 return ((stop - start) * 0.0343) / 2 219 220def get_distance_u1(): 221 global us1_distance 222 223 # send the trigger wave 224 us1_trig(1) 225 sleep_us(1) 226 us1_trig(0) 227 228 # listen for the return echo 229 while us1_echo.value() == 0: 230 start = ticks_us() 231 while us1_echo.value() == 1: 232 stop = ticks_us() 233 234 return ((stop - start) * 0.0343) / 2 235 236 237# ----------------------------------------- 238# LCD 239# ----------------------------------------- 240lcd_init() 241lcd_clear() 242# lcd_cursor_on() 243# lcd_cursor_blink() 244# ----------------------------------------- 245# ADC 246# ----------------------------------------- 247adc0 = ADC(26) # Connect to GP26, which is channel 0 248adc1 = ADC(27) # Connect to GP27, which is channel 1 249# adc2 = machine.ADC(28) # Connect to GP28, which is channel 2 250# adc_reading = adc0.read_u16() * VOLT_PER_BIT # read and report the ADC reading 251 252 253# ----------------------------------------- 254# DAC 255# ----------------------------------------- 256index = 0 257selected_wave = None 258 259 260# ----------------------------------------- 261# TIMERS 262# ----------------------------------------- 263spi_timer = Timer() 264 265def spi_timer_tick(timer): 266 """Process that sends waveform data to the DAC via SPI""" 267# spi_timer.init(freq=frequency*selected_wave.size, mode=Timer.PERIODIC, callback=spi_timer_tick) 268 269 global frequency 270 global amplitude 271 global selected_wave 272 global index 273 global cs 274 275 if selected_wave is not None: 276 277 # output the waveform to DAC via SPI 278 279 # complete math for the value that we send to the DAC 280 dac_output = int((selected_wave.lut[index] * (amplitude / AMP_MAX)) + DC_OFFSET_RES) 281 282 # bit shift so the value is acceptable by the 10 bit DAC 283 284 # A3 A2 A1 A0 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 X1 X0 285 word = (0x9 << 12) + (dac_output << 2) 286 format_array = [((word & 0xFF00) >> 8 ), (word & 0x00FF)] 287 write_array = bytearray(format_array) 288 289 # write to the device 290 cs(0) 291 spi.write(write_array) 292 cs(1) 293 294 # iterate through the waveform tables. 295 index += 1 296 index &= selected_wave.last_index 297 298 299# ----------------------------------------- 300# PROCESS 1: IO 301# ----------------------------------------- 302 303 304while True: 305 306 splash = True 307 # Display the splash screen on startup. 308 if splash is True: 309 led0(1) 310 led1(1) 311 led_onboard(1) 312 lcd_puts(f'USonic Theremin ') 313 lcd_goto(0,1) 314 lcd_puts(f'Dieter S. ') 315 sleep(2) 316 lcd_home() 317 lcd_clear() 318 lcd_puts(f'System Clock') 319 lcd_goto(0,1) 320 lcd_puts(f'{freq()/1e6}MHz') 321 sleep(2) 322 lcd_home() 323 lcd_clear() 324 led0.toggle() 325 led1.toggle() 326 led_onboard.toggle() 327 328 # Start timers and threads 329 reset = False 330 menu_select = 0 331 saved_frequency = 0 332 frequency = 0 333 amplitude = 0 334 freq_min = FREQ_MIN 335 freq_max = FREQ_MAX 336 amp_max = AMP_MAX 337 amp_min = AMP_MIN 338 339 # ----------------------------------------- 340 # Core Loop with reset 341 # ----------------------------------------- 342 while reset is False: 343 344 345 # read ADC rotary controls 346 # ----------------------------------------- 347 adc0_reading = 3.3 - (adc0.read_u16() * VOLT_PER_BIT) 348 adc1_reading = 3.3 - (adc1.read_u16() * VOLT_PER_BIT) 349 # print(f'ADC0: {adc0_reading}') 350 # print(f'ADC1: {adc1_reading}') 351 352 # Read Ultrasonic Sensors 353 # ----------------------------------------- 354 us0_distance = get_distance_u0() 355 us1_distance = get_distance_u1() 356 # print(f'US0: {us0_distance}') 357 # print(f'US1: {us1_distance}') 358 359 # read switch controls and get selected wave 360 # ----------------------------------------- 361 switch_list = [] 362 for switch in switch_pins: 363 switch_list.append(switch()) # read switch and put val in list 364 365 if switch_list.count(1) != 1: # if none of the switches are high. 366 selected_wave = None 367 368 else: 369 switch_key = "SW" + str(switch_list.index(1)) 370 selected_wave = waveforms.get(switch_key) 371 372 # MENU LOGIC 373 # ----------------------------------------- 374 375 if menu_select == 0: # Default Menu, Show wave and frequency 376 377 wave_str = f'Wave: None ' if selected_wave is None else f'Wave: {selected_wave.name}' 378 379 # display the current waveform and frequency 380 # ----------------------------------------- 381 lcd_puts(wave_str) 382 lcd_goto(0,1) 383 lcd_puts(f'F: {frequency}Hz A: {amplitude}V ') 384 lcd_home() 385 386 elif menu_select == 1: # Change range of waveform frequency 387 388 freq_min = round((FREQ_MAX) * (adc0_reading / ADC_REF), 1) 389 freq_max = round((FREQ_MAX) * (adc1_reading / ADC_REF), 1) 390 391 # display the upper bound and lower bound 392 # ----------------------------------------- 393 lcd_puts(f'Upper: {freq_max}Hz ') 394 lcd_goto(0,1) 395 lcd_puts(f'Lower: {freq_min}Hz ') 396 lcd_home() 397 398 elif menu_select == 2: 399 400 amp_min = round(AMP_MAX * (adc0_reading / ADC_REF), 1) 401 amp_max = round((AMP_MAX) * (adc1_reading / ADC_REF), 1) 402 403 # display the upper bound and lower bound 404 # ----------------------------------------- 405 lcd_puts(f'Upper: {amp_max}V ') 406 lcd_goto(0,1) 407 lcd_puts(f'Lower: {amp_min}V ') 408 lcd_home() 409 410 411 # Dual Core Interaction 412 # ----------------------------------------- 413 414 # out of range, stop the waveform process. 415 if us1_distance > MAX_DIST_US1 or us0_distance > MAX_DIST_US0: 416 # spi_timer.deinit() 417 frequency = 0 418 amplitude = 0 419 420 else: 421 frequency = round(((freq_max - freq_min) * ((MAX_DIST_US0 - us0_distance) / MAX_DIST_US0)) + freq_min) 422 amplitude = round(((amp_max - amp_min) * ((MAX_DIST_US1 - us1_distance) / MAX_DIST_US1)) + amp_min, 1) 423 424 if selected_wave != None: 425 spi_timer.init(freq=frequency*selected_wave.size, mode=Timer.PERIODIC, callback=spi_timer_tick) 426 else: 427 spi_timer.deinit() 428 429 # toggle onboard LED for System speed status and refresh delay 430 # ----------------------------------------- 431 led_onboard.toggle() 432 utime.sleep_ms(REFRESH_PERIOD) 433 434 spi_timer.deinit() 435 436# ----------------------------------------- 437# PROCESS 2: Waveform Generation 438# ----------------------------------------- 439 440# while True: 441# if frequency != 0: 442# 443# if frequency != saved_frequency and selected_wave is not None: 444# spi_timer.init(freq=frequency*selected_wave.size, mode=Timer.PERIODIC, callback=spi_timer_tick) 445# saved_frequency = frequency 446# 447# else: 448# spi_timer.deinit() 449# 450# 451 452 453# ----------------------------------------- 454# END OF FILE 455# ----------------------------------------- 456 457

References

- 1(1,2,3,4)

A. S. Sedra, K. C. Smith, T. C. Carusone, and V. Gaudet, “Chapter 2: Operational Amplifiers,” in Microelectronic circuits, New York, NY: Oxford University Press, 2021, pp. 60–73.

- 2(1,2,3)

“What is a bypass capacitor? tutorial: Applications,” Electronics Hub, 14-Sep-2021. [Online]. Available: https://www.electronicshub.org/bypass-capacitor-tutorial/. [Accessed: 27-Aug-2022].

- 3(1,2)

“Analog-to-digital converter,” Wikipedia, 09-Oct-2022. [Online]. Available: https://en.wikipedia.org/wiki/Analog-to-digital_converter. [Accessed: 19-Oct-2022].

- 4

“Digital-to-analog converter,” Wikipedia, 13-Jun-2022. [Online]. Available: https://en.wikipedia.org/wiki/Digital-to-analog_converter. [Accessed: 19-Oct-2022].

- 5

H. Zumbahlen, “Chapter 8: Analog Filters,” in Linear Circuit Design Handbook, Oxford: Newnes, 2008.

- 6(1,2)

“HC-SR04 User Manual,” Scribd. [Online]. Available: https://www.scribd.com/document/363064776/HC-SR04-User-Manual. [Accessed: 14- Nov-2022].

- 7(1,2)

I. Poole, “OP AMP frequency response & gain bandwidth product,” Electronics Notes, 30- Nov-2021. [Online]. Available: https://www.electronicsnotes.com/articles/analogue_circuits/operational-amplifier-op-amp/gain-bandwidthproduct-frequency-response.php. [Accessed: 31-Oct-2022].

- 8(1,2,3)

“LM2940x 1-a low dropout regulator datasheet (rev. J) -Texas Instruments,” Texas Instruments. [Online]. Available: https://www.ti.com/general/docs/lit/getliterature.tsp?genericPartNumber=LM2940C&fileType=pdf&HQS=ti-null-null-alldatasheets-df-ds-null-wwe&DCM=yes. [Accessed: 14-Nov2022].

- 9(1,2)

“LM386,” LM386 data sheet, product information and support | TI.com. [Online]. Available: https://www.ti.com/product/LM386. [Accessed: 30-Oct-2022].

- 10(1,2,3,4)

“Ltc1661 – micropower dual 10-bit DAC in MSOP - Analog Devices.” [Online]. Available: https://www.analog.com/media/en/technical-documentation/data-sheets/1661fb.pdf. [Accessed: 17-Oct-2022].

- 11(1,2)

M. Stapleton, “Altium Designer 20 Video Series,” YouTube, 2021. [Online]. Available: https://www.youtube.com/channel/UCutfTyfmz-WB2hYA03RRN5A/featured. [Accessed: 27-Aug-2022].

- 12

“MicroPython documentation,” Overview - MicroPython 1.19.1 documentation, 14-Oct2022. [Online]. Available: https://docs.micropython.org/en/latest/. [Accessed: 19-Oct2022].

- 13(1,2,3,4,5,6)

“Raspberry Pico Datasheet,” raspberrypi.com. [Online]. Available: https://datasheets.raspberrypi.com/pico/pico-datasheet.pdf. [Accessed: 15-Nov-2022].

- 14(1,2,3,4)

“Raspberry Pico python SDK,” raspberrypi.com. [Online]. Available: https://datasheets.raspberrypi.com/pico/raspberry-pi-pico-python-sdk.pdf. [Accessed: 15- Nov-2022].

- 15

“RP2040 Datasheet,” raspberrypi.com. [Online]. Available: https://datasheets.raspberrypi.com/rp2040/rp2040-datasheet.pdf. [Accessed: 14-Nov-2022].

- 16(1,2,3,4)

“Serial peripheral interface,” Wikipedia, 27-Sep-2022. [Online]. Available: https://en.wikipedia.org/wiki/Serial_Peripheral_Interface. [Accessed: 19-Oct-2022].

- 17(1,2)

“Sitronix ST7066U - Crystalfontz,” crystalfontz. [Online]. Available: https://www.crystalfontz.com/controllers/Sitronix/ST7066U/438. [Accessed: 03-Oct2022].

- 18

“What is a Bypass Capacitor?,” What is a bypass capacitor? [Online]. Available: http://www.learningaboutelectronics.com/Articles/What-is-a-bypass-capacitor.html. [Accessed: 27-Aug-2022].